In electronic circuits, resistors are the passive two-terminal devices used to regulate or reduce the flow of current in the circuit. Mostly fixed type resistors are used in the electronic circuits because of its fixed resistance value. The resistance is determined during the manufacturing process itself and it can’t be varied like a variable type resistor. Based on the manufacturing process, the fixed type resistors are divided into 4 types such as carbon resistors, wire wound resistors, thin-film resistors, and thick film resistors. The carbon composition resistors are of two types such as carbon composition resistors, and carbon film resistors. The ratio of carbon mixture to the ceramic dust determines the resistance of the carbon resistors. This article describes the carbon composition resistor.

What is Carbon Composition Resistor?

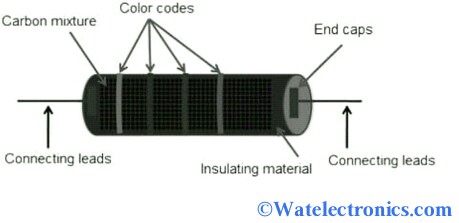

Definition: The carton composition resistor is a two-terminal carbon type resistor that opposes or reduces or restricts the excess current flowing through the electrical and electronic circuits. These are used as general-purpose resistors. These are fixed resistors. These types of resistors are most widely used in the earlier 1960s. These are less expensive, and smaller in size. These can withstand over high energy pulses generated in the circuit. But these days, these types of resistors are rarely used due to the high cost, poor stability, noise, high sensitivity, and smaller power dissipation capacity. The diagram of the carbon composition resistor is shown below.

Carbon Composition Resistor Diagram

History of the Carbon Composition Resistor

The carbon composition resistors are most widely used in the earlier days of the 1960s due to their special specifications like tolerance, voltage dependence, and stress over high voltages. These types of resistors are used in the circuits for almost 100 years along with the wire wound resistors. The carbon composition resistors are widely used in welding controls, high power supplies, and electronic circuits.

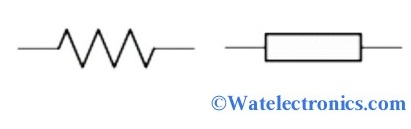

Later on in the year the 1970s, the usage of these resistors is reduced and other types like carbon film resistors metal film resistors came into existence due to the high tolerance, and high precision. The carbon composition resistors are rarely used due to their high cost, poor stability, and small size. The symbol of the carbon composition resistor is the same as that of the normally fixed resistor shown below.

Symbol

Carbon Composition Resistor Timeline

The carbon composition resistors are the first passive fixed resistor introduced along with wire wound resistors. In the earlier 1960s, these types of carbon resistors are used with a tube or valve irrespective of size. But later on, the transistor-based equipment needs a small resistor with good performance and the carbon composition resistors requirement decreased. The use of carbon film and metal oxide film resistors came into existence. Even though the carbon composition resistor used for a specific high-frequency application.

In the earlier 20th century, the carbon composition resistor is available with uninsulated bodies. That means the electrodes of the carbon composition resistor were wrapped around the resistive elements ends and then soldered. In order to provide the coding, it was painted with colors and calculated its value.

Later on, these types of resistors are available with the ceramic body to protect themselves from the external environment. These are mostly used and familiar in an old tube or valve radios.

Construction

The construction of the carbon composition resistor can be explained from the diagram as shown above.

It uses a cylindrical shaped solid resistive element, which is formed by the blending of carbon particles, graphite powder, and ceramic powder (made with clay). There are two connecting leads or electrodes at both ends of the resistive element. These leads or electrodes are also known as metal cap ends, and are made with copper. Since the carbon mixture is mainly used in construction because it is the good conductor of electricity.

An insulating material like plastic is wrapped around the resistive element to protect the carbon composition from the dust, heat, and other environmental conditions. In the earlier 1960s, there is no insulating material. Hence the carbon composition resistor is used to get damaged due to the heat at low temperatures.

The carbon composition resistors are normally called as carbon resistors available within the range of 1Mega Ohm to 22 Mega Ohms resistance. The color codings on the top of the resistive element the resistance of the carbon composition resistor.

There two types of color codings. They are general coding and precision coding.

General Coding

It includes 4 color codings with a tolerance of greater than ±5%. The numeric values are represented by the first two color bands, while 3rd is for multiplier and 4th is for tolerance. These types of codings are used in general-purpose resistors.

Precision Coding

To evaluate the resistance of the carbon composition resistor, precision coding includes 5 color bands with tolerance <±2%. The first three bands represent numerical values, fourth is for multiplier and fifth is for tolerance.

Specifications

The typical carbon composition resistor specifications are

- The tolerance will be ±5%, ±10%, ±20%

- The resistance value ranges from 1 Mega to 22 Mega Ohms

- Its load life will be +4 (percentage change over 1000h)

- Maximum of noise 6µV/V

- Temperature coefficient >±1000 ppm/°C

- Voltage coefficient of 0.05%/V

- Maximum temperature of resistance 120°C

- Remains stable against high energy pulses

- Higher reliability, low cost, and small size

- Better frequency response due to the pure resistance

- Voltage ratings will be 400V, 700V, and 1000V based on the application

- Temperature ratings will be -55°C to 125°C

- Ratings of the power range from 1 to 5 Watts for electronics circuit applications

Carbon Composition Resistor Function

The carbon composition resistors are also known as general-purpose resistors or carbon resistors used in various electronic and electrical circuits. These are very cheap, smaller in size, safe for all types of circuits. The main function of the resistance of the carbon composition resistor is to restrict or oppose or reduce the excess flow of current in the circuit. It reduces the sudden voltage spikes, lightning surges induced due to the high voltage power supplies. So, these are used in surge protection circuits.

These can tolerate overload conditions in the circuit.

These types of resistors are used in high-frequency applications, current limiting circuits, and high voltage power supplies due to their low cost, smaller size, and high stability over high energy pulses. But nowadays, the carbon composition resistors are rarely used due to their size, cost, and stability.

There are 3 factors, which will have a greater impact on the resistance of the carbon composition resistors. The resistance of these resistors changes due to the following factors.

- As the mixture of carbon used in the construction is more, then the resistance of the resistance is low. Since carbon is a good conductor of electricity.

- Longer the length of the resistive element provides higher resistance.

- The cross-sectional area of the resistive element is inversely proportional to the resistance. Since the resistive element is in a cylindrical shape.

Advantages

The advantages of carbon composition resistors are

- These are available in small sizes

- It is also a fixed resistor and it is available at affordable rates ie., the cost is low.

- These types of resistors have an ability to tolerate high energy pulses due to the higher thermal mass

- The resistance of the carbon composition resistor is high

- Provides higher reliability.

Disadvantages

The disadvantages of carbon composition resistors are

- The resistance of the carbon composition resistor changes quickly. So, it has poor stability.

- It produces high noise

- The accuracy is low

- The resistance changes (increase or decrease) due to the absorption of water. The water absorption is another main drawback.

- These are sensitive due to the change in temperature

- The ability of power dissipation is poor.

- The operating temperature and power ratings are limited.

Applications

The applications of carbon composition resistors are

- Used in circuits for surge protection

- Used in current limiting circuits

- Used in electronic circuits for general purposes.

- Used in welding controls

- Used in power supplies of high voltages

- Used in high-frequency range applications

- Used in strobe lighting

- Used in protecting the circuit or device against high energy pulses.

Thus, this is all about the carbon composition resistor – definition, diagram, symbol, function, construction, specifications, timeline, advantages, disadvantages, and applications. Here is a question for you, “What are carbon film and wire-wound resistors?”