Splicing of optical fibers is a fundamental method to connect two optical fibers permanently. Since the optical fibers are laid for long distances, which may even go up to hundreds of kilometers, it is not possible to lay a single line for such along with distance. Hence it becomes necessary to join two cables at certain points to increase the span of the cable. A lot of care is taken in splicing the fiber cables. It must be noted that, while joining the cables, no discontinuity should arrive in transmitting the data.

Otherwise, the cables would lose their functionality and would be of no use. Since the transmission of data through optical fibers is made at a very high frequency, while splicing the cables is must be noted to maintain the frequency spectrum. Otherwise, it could cause a loss of efficacy in data transmission. Usually, special machines are devised for optical splicing. In this article, we will different methods, advantages, and other aspects of optical splicing.

What is the Splicing of Optical Fibers?

Optical Splicing is a method of connecting two optical fibers permanently. This process becomes important when the optical fiber cables are laid for long distances.

Optical Fibers

Since it is not possible to go for the single long line, generally more optical fiber cables are joined together from source to destination. There are some basic requirements for optical fiber splicing which are mentioned below.

Basic Requirements of Optical Fiber Splicing

The basic requirements of optical fiber include the following.

- Splicing of Optical Fibers Should Cause Minimum Loss: It should be noted that, while splicing two fiber cables, the loss in the continuity should be minimum. The loss of the data must be completely avoided. The loss in the cable material may be compensated in the overall calculation.

- Easy Installation: The installation should be easy. People are trained in this aspect and made sure that, after installation, it doesn’t cause any data loss.

- Low Attenuation: It should not cause any reduction in the signal strength or frequency. The splicing process should be efficient enough to maintain the attenuation of the transmitted signals. Attenuation in the signal strength causes loss of data and poor receiving end modulation. Attenuators can not be maintained at every point in the span of optical fiber length to avoid data transmission.

- Mechanically Strong: The splicing of the cables should be mechanically strong. In most cases, the fibers are transported over a long distance for physical laying. In such scenarios, the cables should not be fragile. In every transportation process, the most vulnerable points are the splicing joints. Hence it is ensured that the joints are mechanically strong.

- Less Weight: The splicing factor should not cause the addition of weight to the overall cable. Therefore the splicing should be light in weight.

Splicing Techniques of Optical Fiber

There are fundamentally two methods for the splicing of the optical fibers.

- Fusion Splicing

- Mechanical Splicing

Both the methods are explained in detail below.

Fusion Splicing

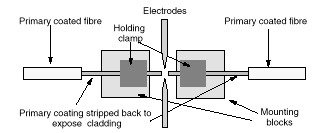

As shown in the figure, for fusion splicing the optical fiber is held between two electrodes. The major equipment used for this arrangement is, an optical fiber, holding clamp, primary coating stripped back to expose the cladding and the mounting blocks. In the olden days, a V-shaped grove was used in place of mounting blocks.

Fusion Splicing

The main purpose of mounting blocks is to hold the cable firm while splicing. It is made sure that the fiber is easily fixed in the mounting block. Two electrodes are placed at the top and bottom of the fiber. The main functionality of the electrodes is to provide heat at the surface of the cable. Since the electrodes are provided heat, electric supply must be provided to the electrodes. Generally, they are excited by DC source voltage for the generation of heat. Because of the heat generated, the fiber is spliced at the joint.

The other important points to be noted in fusion splicing are, the two ends of the cable are initially cleaned and polished. This makes the spicing process easy. The optical fiber cables are placed on the mounting blocks. It must be ensured that the fiber must be firmly held during the splicing process.

Otherwise uniform distribution of heat won’t happen, the fiber would be spliced improperly. It would also cause a loss in data and attenuation. The clamps are used to hold the cable firmly during the fusion process. Those are called holding clamps. In some cases, the holding clamps are used to fix it in the tooling fixture. Then the heat from the electrodes is applied to the surface of the cable for joining it.

Advantages of Fusion Splicing

- The various advantages of fusion splicing are

- It gives low attenuation. Due to the elementary technique, i.e. heat which is used to join the fiber, the attenuation caused is very low. Due to this, the data loss in the cables is also very low. This improves the overall efficiency of the system.

- This method improves the overall quality of the joint. The quality is judged in terms of data transfer efficiency and attenuation factor.

- Fusion splicing also causes the small size of the splice. This increases the overall mechanical strength of the fiber, and in fact, reduces the weight which are the desirable characteristics of the splicing.

- This method is cost-efficient and easy to install.

Disadvantages of Fusion Splicing

- One biggest drawback of fusion splicing is the heat may make the optical fiber weak. To overcome this factor, it is made sure that, the heat is uniformly distributed over the surface of the cable. This will avoid the weakening of the cable.

- One more drawback of fusion splicing is after the splicing process, the tensile strength of the fiber may decrease. This is also overcome by the uniform distribution of the heat.

Mechanical Splicing

In this method of splicing, first, the fibers are aligned, and then they are locked in position using various positioning devices. Fundamentally two optical fibers are joined by first aligning the cables, and then locking them. In mechanical splicing also we have different types which are mentioned below.

Precision Tube Splice

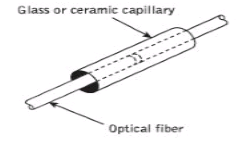

In this process, two fiber cables are inserted in the precision tube and locked. Before that, the fiber ends needs to be cleaned. The splice has a compound that has the same refractive index as fiber, so the two fibers are inserted into the tube and the outer jacket is crimped. Because of crimping, the fiber is fixed inside.

Precision Tube Splice

Loose Tube Splice: In this method, a rectangular tube is used for splicing. An adhesive material is used to join the fiber cable. In this process also, the ends need to be polished before splicing. The adhesive material will have the same refractive index as that of the fiber.

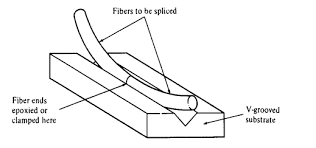

V-groove Splice

V Groove Splice

It is also known as a surface groove splice. For this process, a metal with a V shape groove is taken. The dimension of the groove is taken such that, the fiber is easily fixed in the groove. After placing the fiber, adhesive epoxy material is placed on the V groove such that, the fiber is joined. After placing the adhesive, one metal plate is turned or aligned on the other with the help of a groove and the fiber is joined.

Elastomeric Splice

This is another version of V groove splice. Two elastomeric materials are used which gives compression on the fibers aligned in the V groove.

Precision Pin Splice

In a precision pin splice, a heat shrink tube is used to hold three steel pins together. The fiber pins are inserted in the opening between the three pins. And using the index matching epoxy, the splicing is done. The three steel pins are held together using a heat shrink tube.

Spring Groove Slice

In this process, two cylindrical pins are used for alignment guiding of the optical fiber. Using the spring technique, the fiber is pressed into the groove. Epoxy resin is used for the splicing. The spring provides bracing of the fiber between the cylindrical pins.

Please refer to this link to know more about fiber-optic communications MCQS

Hence we have seen the different methods of splicing the optical fiber. As mentioned earlier, all the basic requirements of optical fiber spicing must be achieved before the process. And one important feature is attenuation must be avoided. One interesting aspect to be seen is that in which units, the loss in attenuation is evaluated during the fusion splicing or mechanical splicing in the process of optical fiber splicing? And how do we take measures to avoid the loss is also important.