Tantalum Capacitor is among one of the types of the ‘Electrolytic capacitors’. This type of capacitor is Polarized in nature. In this capacitor a porous tantalum metal is used as Anode. It is further covered by the conductive layer known as Cathode. There is a layer of oxide present in it which acts as the Dielectric. It is known for the capability of generating higher amounts of capacitance/volume.

The reason for generating the capacitance high is that the dielectric in it is of very thin type apart from that they occupy less space so they are most popularly found on laptops .

What is Tantalum Capacitor?

A capacitor with a terminal of ‘Tantalum’ metal as an anode can be defined as the Tantalum Capacitor. The polarized nature of these capacitors makes it suitable in the dc supplies. While connecting this capacitor in any circuit the polarity of the terminals need to be considered.

Tantalum Capacitor Symbol

The above figure represents the symbol of tantalum capacitor. When positive voltage is applied to the anode terminal a oxide layer forms on the anode, which acts as the dielectric. The dielectric which forms in this capacitor is generally a thin layer around 1.7nm/v. The size of the dielectric depends on the amount of the voltage applied. Then after the formation of an oxide layer it is then dipped into an electrolyte solution which acts as the cathode . That’s how a Tantalum capacitor is constructed. As we know a sintered anode terminal will increase the capacitance of the capacitor. Similarly in tantalum capacitor also the anode terminal is sintered by which the electrode area increase and so its capacitance also. The Tantalum capacitors work on the principle of ‘Electrolytic Capacitors’.

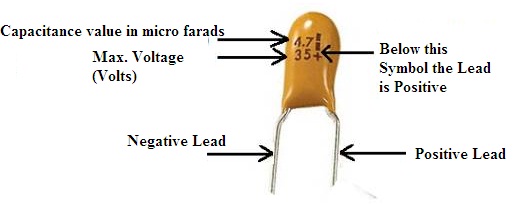

Tantalum Capacitor Polarity and Markings

- These capacitors are known for their Polarized behavior.

- Only the capacitor made with Aluminum as anode can be able to tolerate the voltages in reverse and these capacitors are unable to tolerate it. It leads to the condition that breaks the Dielectric present in it. This may even result in the ‘Short Circuit’.

- These circuits possess positive and negative terminals.

- The positive one stands for the anode. The negative one is the cathode.

- While in the case of this capacitor the + symbol is marked on it.

Tantalum Electrolyte Capacitor

Failure

There exists a mode called Failure in this capacitor. It is due to the spikes of voltage. The anode of this capacitor responds to these spikes which reacts with the Manganese Dioxide, an electrolyte which acts as the cathode. The energy released due to the spike becomes sufficient for the ‘Chemical Reaction’ to take place.

It leads to the generation of heat in the capacitor. Further production of heat leads to the production of the flame and the smoke. This condition is referred to as ‘Thermal Runaway’. This type of condition can be prevented by the help of preventive circuits which are known as ‘Thermal Fuses’ or ‘Current Limiters’.

Uses and SMD Sizes

These types of capacitors are known for their highly stablility and reliablility. The current leakage is low in these capacitors. The uses of these capacitors are:

- These are utilized in the circuits of ‘Sample and Hold’. It usually relies on the ‘Low Leakage Current’ so that long holding condition is achieved.

- Because of the stability and the compact size, these are used in the supply circuits for filtering.

- It can be used in the ‘Military Specifications Versions (MIL-SPEC)’. It offers high values of tolerances with a wider range of operating temperatures.

- In the field of electronics which are used in Medical, these capacitors are preferred because of the stable behavior.

- In the practical applications of the Audio Amplifier circuits, Tantalum Capacitors are used.

The above are some of the practical uses of Tantalum Capacitors.

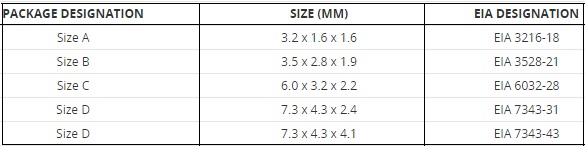

If these capacitors are designed based on the technique of ‘Surface Mounting’ then they are referred to as ‘SMD Tantalum Capacitors’. As the high capacitance, reliablility is available in smaller sizes these are more preferred in PCB’s.

The capacitors made with ‘Aluminum’ are not designed with the ‘SMD’ technique as they are unable to tolerate the ranges of temperature required at the time of soldering. However, the capacitors built with tantalum are preferred for these reasons.

These capacitors of ‘SMD’ can be made in various sizes. These standards are based on the ‘Electronic Industries Alliance (EIA)’.

Tantalum Capacitor SMD Sizes

Difference between Tantalum and Ceramic Capacitor

The difference between the Tantalum and the Ceramic capacitors are as follows:

|

Tantalum Capacitor |

Ceramic Capacitor |

| 1. These capacitors are Polarized. | 1. These capacitors are not Polarized. |

| 2. The part of Tantalum coating is referred to as a positive terminal. | 2. The Dielectric chosen in this capacitor is of Ceramic. |

| 3. These capacitors possess a large area of the plate. | 3. In comparison to Tantalum capacitors, these capacitors possess less overall plate area. |

| 4. The layer of Dielectric is Thin. | 4. The layers of Dielectric are thick in comparison to other capacitors. |

| 5. It cannot tolerate Reverse Voltages. | 5. It can tolerate a reverse voltage |

| 6. The symbol of this capacitor is as follows

|

6. The symbol of this capacitor is as follows

|

The above are the basic differences that give a comparison between both ceramic and the tantalum capacitors.

Tantalum Capacitors are mostly known for their ‘Packed Densities’. These are compact sizes. Because of its stabilized nature these are preferred over ‘Aluminum Electrolytic Capacitors‘. Its consistency as discussed above results in achieving high amounts of gains.

The compactness and the efficiency makes it a ease for flexible operations for the modern electronic equipment’s. The limiting circuits provided as extensions of this circuits acts as protectants. The necessity of these limiters is due to the polarizing effect involved in this capacitor. And to avoid any reverse connection a marking of the ‘+’ sign is done on the capacitor. The markings and its classification based on polarity must be handled with care.

Please refer to this link to know more about Mica Capacitor.

Based on the points discussed above can you tell what must be the operating voltage range of the Tantalum Capacitor?