Surface-mount technology or SMT-based components like resistors; capacitors, etc are used in huge quantities. SMT is an alternative to through-hole (TH) PCB design. SMT is a process where the electrical components are placed on a PCB (printed circuit board) directly. So, the process of mounting a component in this way is known as SMD (surface-mount device). At present, most industries like consumers, electronics are using this technology because this technology improves manufacturing, reliability, allows high levels of functionality, and reduces size and cost. By using this technology, we can make printed circuit boards more efficient without losing any quality or reliability. Surface mount devices or SMDs replace heavier, larger & weighty parts in the through-hole PCB design. This article discusses an overview of SMD resistor, working, and its applications.

What is SMD Resistor?

SMD resistor is one kind of electronic component where the SMD stands for Surface Mounted Device. This component uses surface mount technology. The main intention of SMT is to provide more efficient, faster & less cost smaller components to use by printed circuit board manufacturers. As compared to traditional components, SMD components are very small in size and also available in different shapes like rectangular, oval, square, etc.

SMD Resistor

SMD components have small pins or lead instead of wire leads so that we can easily solder to pads on the board surface. So that it eliminated the holes within the PCB and allows using both faces of the board. Once the printed circuit board is manufactured, then these resistors are located on it through a pick & place machine. These machines can place thousands of components for each hour. Finally, a visual inspection verifies for the components which are missing otherwise out-of-position and also whether the board is clean or not.

SMD Resistor Construction

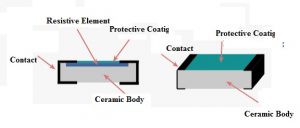

The construction of the SMD resistor can be done in a rectangular shape. In this resistor, a metalized area is present at any one face of the component which allows connecting with PCB through soldering.

A ceramic substrate is one of the parts of this resistor where metal oxide film can be deposited over it. The resistance of this resistor can be determined through the length as well as thickness of the actual film.

SMD Resistor Construction

In SMD resistors, metal oxide plays a key role to allow the resistor to be stable by maintaining the tolerance level high. The ceramic substrate element in this resistor is made up of high alumina ceramic which provides stable insulation on the base of the element of resistive metal oxide on which the SMD resistor is set aside.

The contact of this resistor which is made with a resistive element of chip resistor must be reliable and also it should give extremely high levels of solderability. These high levels can be achieved by using the nickel-based layer to create an inner connection. And also, the external layer which is based on a tin can be used to create the external connection thus very high levels of solderability can be achieved.

Affecting Factors

Generally, the malfunction rate of resistors is fairly high as compared to other components. However, this rate will rise at high temperatures & high pressure, so in some situations, we need to estimate the life of the resistor carefully. The resistor life can be effected through the following factors.

- The resistor can be damaged if the temperature is very high.

- The alkalinity & acidity of the surroundings openly rusts the resistance & cause harm.

- Once the outside force exceeds a fixed limit, then the resistance will break.

So to overcome these issues, the resistor life needs to extend by maintaining power dissipation good, maintain a dry environment to prevent burning, free of toxins & external forces need to avoid. A high resistance value resistor will have a fairly long life.

SMD Resistor Specifications

The specifications of the SMD resistor include the following.

There are many manufacturing companies are available to manufacture SMD resistors but the specifications of these resistors mainly change based on the manufacturer. Therefore, before using SMD Resistors, one has to verify the manufacturer’s rating for the resistor. The specifications of the SMD resistor include the following.

Power Rating

The power rating of the SMD resistors-based circuit designs uses very smaller levels as compared to the wire-ended components-based circuit designs. The power rating of this resistor mainly depends on the size. For different sizes, it is feasible to simplify the power ratings of different sizes of SMD resistors.

Typical SMD resistor power ratings are listed below.

- For the 2512 package style, the typical power rating is 0.50 or 1/2

- For the 2010 package style, the typical power rating is 0.25 or 1/4

- For the 1210 package style, the typical power rating is 0.25 or 1/4

- For the 1206 package style, the typical power rating is 0.125 or 1/8

- For the 0805 package style, the typical power rating is 0.1 or 1/0

- For the 0603 package style, the typical power rating is 0.0625 or 1/16

- For the 0402 package style, the typical power rating ranges from 0.0625 to 0.031 or 1/16 to 1/32

- For the 0201 package style, the typical power rating is 0.05

Tolerance

The SMD resistors toleranc\e values which utilize the metal oxide film are extremely close for their designing. The tolerance values which are accessible at a large scale comprise 1%, 2% & 5%. In addition, the 0.1% & 0.5% values can be attained for the applications.

Temperature Coefficient

For SMD resistors, the values of temperature coefficient utilize the metal oxide film for their manufacturing is extremely high. The levels of temperature coefficients that are accessible at a large scale contain 100 ppm/C & 25,50 ppm/C.

SMD Resistor Packages

The typical SMD resistor packages are shown below.

- For 2512 package style, the size in mm is 6.30 x 3.10 & the size in inches is 0.25 x 0.12

- For 2010 package style, the size in mm is 5.00 x 2.60& the size in inches is 0.20 x 0.10

- For 1812 package style, the size in mm is 4.6 x 3.0 & the size in inches is 0.18 x 0.12

- For 1210 package style, the size in mm is 3.20 x 2.60 & the size in inches is 0.12 x 0.10

- For 1206 package style, the size in mm is 3.0 x 1.5 & the size in inches is 0.12 x 0.06

- For 0805 package style, the size in mm is 2.0 x 1.3 & the size in inches is 0.08 x 0.05

- For 0603 package style, the size in mm is 1.5 x 0.08 & the size in inches is 0.06 x 0.03

- For 0402 package style, the size in mm is 1 x 0.5 & the size in inches is 0.04 x 0.02

- For 0201 package style, the size in mm is 0.6 x 0.3 & the size in inches is 0.02 x 0.01

SMD Resistor Markings

Many of the SMD resistors don’t include any markings on the resistor. These markings indicate the resistor value. Once these values are erased or loosed then finding the component values is very difficult. So, SMD resistors include the values in reels otherwise other packages wherever there is no possibility to mix with different values.

SMD components include markings on them. In the coding system of SMD resistor, there are two systems are used:

- Coding system for 3 figure SMD Resistor

- Coding system for 4 figure SMD Resistor

In 3 figure SMD resistor, the first two letters indicate significant values whereas the third one indicates the multiplier. For example, if the resistor has 322, then the resistance value is 32 x 102 ohms.

In the 4 figure SMD resistor, the first three letters indicate significant values whereas the 4th one indicates the multiplier. For example, if the resistor has 3212, then the resistance value is 321 x 102 ohms.

Advantages & Disadvantages

The advantages of SMD resistor include the following

- Size

- The density of component is high

- Less cost

- Simple and fast to connect

- Small errors can be corrected easily

- On both faces of the board, components can be placed.

- Reduced inductance

- Mechanical performance is good

- Accuracy and tolerance

The disadvantages of SMD resistor include the following

- Power rating

- Rework

- These components cannot be used with breadboards directly

- Component repair is difficult

- SMT is not applicable for high-power, large, high-voltage parts like power circuitry

- Small power & volume

- Sensitive

Thus, this is all about an overview of the SMD resistor which uses surface mount technology. The main benefits of using this technology are, high signal transmission speed, effects of high frequency are good, SMT is helpful in automatic production, efficiency improving and material cost is less. Here is a question for you, what is SMD?