SMD capacitor is the capacitor designed with different technology. SMD sometimes referred to as SMT which means ‘Surface Mounted Technology’. This technology is about manufacturing the capacitors with such ease so that bulk manufacturing becomes easier. In this technology the capacitor is designed without leads. This makes convenient in placing the printed circuit boards (PCBs).

With the use of this technology, various types of capacitors namely Ceramic and Tantalum are designed. Among those Ceramic ones are the most predominant ones. The ease of manufacturing reduces the final productivity cost. Based on the respective codes and the design one can identify the variant of it. Overall this technology is utilized in modern designs due to its reduced size and flexible connections. Further, this modification has its disadvantages. Still, modifications are undergoing to achieve efficient results.

What is SMD Capacitor?

A capacitor that is designed with the ‘Surface Mounted Technology’ can be referred to as an SMD capacitor. Instead of leads, it possesses the metals to provide convenient connections. Because of this, the value of the inductance is less. Hence it makes these capacitors more flexible.

SMD Capacitor working principle and Types

The capacitor can be electrolytic or non-electrolytic can be manufactured using SMD technology. Other than this there is no difference noticed in the construction of it. There will be two electrodes that are separated by the material that has insulating properties. Based on the supply provided the flow of charge occurs and charging and the discharging of the capacitor occurs. To know more on click on how a capacitor works ?

Basing on the type of the ‘Dielectric material’ chosen there are various capacitors classified. Some of the widely preferred ones are discussed here.

- Ceramic SMD Capacitors

These capacitors consists of the dielectric made of ceramic material. Inside it metal electrodes are present. A multi layer concept is utilized in its process of designing. Because of this structure, the value of capacitance is huge per single quantity of volume. By using ‘silver palladium’ alloy or by the barrier initially made with silver and coated with the nickel and the final coating of tin is applied over it. These capacitors after coating are heated on the temperatures about a range of 1100 to 1300 degrees Celsius. Certain techniques and precautions were taken while designing these Ceramic Capacitors.

- Electrolytic SMD Capacitors

The SMD technique can be applied to the electrolytic capacitors. This makes the design and cost convenient. The manufactured ones can be identified by certain codes printed on them. It consist of markings to represent the values of the ‘Working Voltages’. The functionality of it remains the same.

- Tantalum SMD Capacitors

To achieve the higher range of capacitance the tantalum capacitors are preferred. It follows the ‘EIA’ specifications in terms of design and the value of capacitance and its coding to identify the value of the capacitor. Basing on these various packages of it is designed.

By following certain respective standards, marking and coding techniques these capacitor values are identified.

SMD Capacitor Codes, Polarity, Sizes and Identification

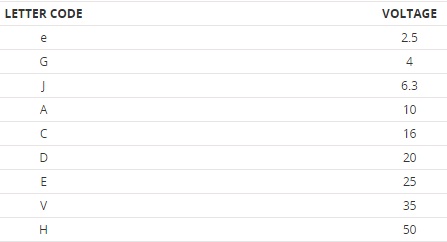

The essential classification of a capacitor that has been designed with polarity is differentiated. Other than that the remaining characteristics don’t change. Certain codes are followed in electrolytic capacitors manufactured with SMD technique. In this, the units named micro farads are printed directly on it. In some cases, these capacitors can be identified with the help of codes on it. In some situations, there codes are represented using alphabets which are based on the fixed standards.

SMD Capacitors- Electrolytic Codes

On some specific capacitor, the three-digit code is present. In which the last digit is treated as the multiplier. The units are measured in terms of farads. As discussed earlier that these capacitors manufactured don’t consist of leads. Hence the design of it is compact in size. By adopting various latest techniques the size is even minimized and made comfortable for the design criterion of various modern pieces of equipment.

SMD Capacitor-Tantalum

Let us consider the above example of the SMD tantalum capacitor. On it, one can notice the value of capacitance printed. Therefore, the various values of the capacitors are identified based on the standard followed by it. Sometimes it is printed as 33.6 where the value of the capacitance can be determined as 33 micro farads and the number after the decimal point indicates the value of the working voltage.

Uses :

The reduced size, convenience in terms of the absence of leads, flexible with the help of coding makes this capacitor a predominant in modern devices. Because of these reasons, there are many practical uses of these capacitors. However, the basic properties of the capacitor manufactured with the SMD technique only gains certain changes but rest of the properties remains the same. In the high-end frequency applications, these are preferred.

Ceramic capacitors are more preferred for a reduced sized SMD capacitors. They use the concept of multiple layers during its manufacturing. Even the minimize nature of size has a drawback. It makes difficult to handle it for connections. It has certain limitations if it is pushed over it then the capacitor gets damaged. During the design of the mass application-oriented pieces of equipment, these capacitors are mounted on it. But with the surface mounted technology the capacitors designed results in the low cost.

Finally, we can say that this technology has a wide area and scope of applications. Along with it certain precautions and preventive measures are also taken during this utilization of capacitors. Further information about these capacitors can be obtained in its datasheet of SMD Capacitor. Now can you identify various SMD capacitors and note its capacitance values?