Programmable Logic Controllers (PLCs) serve as the brains of industrial automation, controlling machinery and processes to ensure efficiency and precision. One of the critical aspects of PLC programming is the selection and use of programming languages. PLC programming languages are specialized interfaces designed to communicate with and control the behavior of a PLC. In this article, we’ll delve into the various PLC programming languages, their characteristics, and how they contribute to the functionality of these powerful automation devices.

PLC Programming Languages:

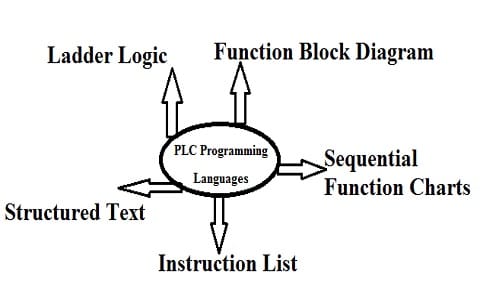

PLC programming languages are symbolic notations used to create control programs that dictate the operation of a PLC. The choice of programming language depends on factors such as the complexity of the task, familiarity of the programmer, and the specific requirements of the application. The major programming languages used in PLCs include:

PLC Programming Languages

Ladder Logic (LAD):

Ladder Logic is the most widely used programming language in PLCs, and its name is derived from the graphical representation resembling a ladder. It employs relay ladder diagrams, making it intuitive for electricians and engineers familiar with relay control systems.

Ladder Logic is ideal for representing discrete logic operations and sequential control, making it well-suited for applications like conveyor systems, traffic lights, and packaging machines.

Function Block Diagram (FBD):

FBD is a graphical programming language that represents functions as blocks connected by lines. Each block performs a specific operation, and the connections define the flow of data between the blocks.

FBD is beneficial for complex systems where modularity and reusability are essential. It is often used in applications involving continuous processes, such as chemical plants and water treatment facilities.

Structured Text (ST):

Structured Text is a high-level programming language resembling Pascal or C. It allows for more sophisticated programming constructs and is well-suited for complex mathematical operations and data manipulation.

ST is favored by programmers with a software development background and is commonly used in applications requiring advanced calculations, data analysis, and algorithm implementation.

Instruction List (IL):

IL is a low-level programming language that uses mnemonic instructions similar to assembly language. Each instruction corresponds to a specific operation or control function.

IL is efficient for experienced programmers who need precise control over the PLC’s operation. It is often used in applications where performance optimization is critical, such as high-speed manufacturing processes.

Sequential Function Chart (SFC):

SFC is a graphical language that divides the control program into a series of steps, similar to a flowchart. Each step represents a specific phase of the process, and transitions between steps are triggered by conditions or events.

SFC is well-suited for representing complex processes with multiple states and transitions. It provides a clear visualization of the sequential nature of the control logic and is commonly used in applications with intricate state-based control requirements.

Choosing the Right Programming Language:

The selection of a programming language depends on the nature of the application and the preferences and expertise of the programmer. Here are some considerations when choosing a PLC programming language:

Application Complexity:

For simple, discrete control tasks, Ladder Logic may be sufficient. However, for applications involving complex calculations or extensive data manipulation, Structured Text or Function Block Diagrams may be more suitable.

Programming Team Expertise:

The expertise of the programming team plays a crucial role. If the team is more familiar with traditional relay logic, Ladder Logic may be preferred. For software developers, Structured Text might be a more comfortable choice.

Modularity and Reusability:

If modularity and reusability are priorities, Function Block Diagrams offer a convenient way to encapsulate functionality into reusable blocks. This can simplify program development and maintenance, especially in large and complex systems.

Real-Time Requirements:

Applications with stringent real-time requirements, such as high-speed manufacturing processes, may benefit from the efficiency of low-level languages like Instruction List.

PLC Programming Languages:

1). Ladder Logic (LAD):

Ladder Logic is based on relay ladder diagrams used in traditional relay control systems. It employs graphical symbols to represent relay contacts and coils, making it easy to understand for those familiar with electrical schematics. The symbols are arranged in a ladder-like fashion, with left-to-right and top-to-bottom flow.

The basic building blocks of Ladder Logic include:

Contacts: Represent input conditions or sensors. They can be normally open (NO) or normally closed (NC).

Coils: Represent output actions or devices. They can be energized or de-energized based on the logic conditions.

Ladder Logic is ideal for representing basic logic operations such as AND, OR, and NOT. It is well-suited for applications with discrete inputs and outputs, making it a popular choice for industries like manufacturing and packaging.

Please refer to this link to know more about – Ladder Logic.

2). Function Block Diagram (FBD):

Function Block Diagram (FBD) is a graphical programming language that uses blocks to represent functions or operations. These blocks can be interconnected to create complex control algorithms. FBD is particularly useful for applications that involve continuous processes and mathematical operations.

Key elements of FBD include:

Function Blocks: These represent specific functions or operations and encapsulate their behavior. Examples include mathematical operations, timers, and counters.

Input and Output Connections: Lines connecting the function blocks represent the flow of data between them.

Control Relationships: The sequence of execution is determined by the connections between blocks. FBD promotes modularity and reusability, allowing programmers to develop libraries of function blocks that can be easily integrated into different projects. It is a powerful tool for applications in chemical processing, water treatment, and other continuous processes.

3). Structured Text (ST):

Structured Text (ST) is a high-level programming language that resembles traditional programming languages like Pascal or C. It provides a textual representation of the control logic, making it suitable for programmers with a software development background.

Key features of Structured Text include:

Variables and Data Types: ST supports variables and various data types, allowing for complex data manipulation.

Structured Programming Constructs: It includes programming constructs such as loops, conditional statements, and functions.

Mathematical Operations: ST is well-suited for applications that require complex mathematical calculations and algorithms.

Structured Text is often used in applications where the control logic involves advanced calculations, data analysis, or algorithmic operations. It provides a high degree of flexibility and expressiveness for programmers familiar with traditional programming languages.

4). Instruction List (IL):

Instruction List (IL) is a low-level programming language that uses mnemonic instructions to represent specific operations. It is similar to assembly language and provides a direct mapping to the underlying hardware of the PLC.

Key characteristics of the Instruction List include:

Mnemonic Instructions: IL uses short mnemonics to represent operations such as AND, OR, compare, and jump.

Registers: IL allows direct access to PLC registers and memory locations.

Efficiency: IL is efficient in terms of execution speed and is often used in applications with high-speed requirements.

IL is suitable for experienced programmers who require fine-grained control over the PLC’s operation. It is commonly employed in applications with strict timing constraints, such as high-speed manufacturing and process control.

5). Sequential Function Chart (SFC):

Sequential Function Chart (SFC) is a graphical programming language that divides the control logic into a series of steps. Each step represents a specific phase of the process, and transitions between steps are triggered by conditions or events.

Key components of SFC include:

Steps: Each step represents a specific state or phase of the process.

Transitions: Transitions define the conditions under which the system moves from one step to another.

Actions: Actions associated with each step represent the specific operations to be carried out.

SFC is beneficial for representing complex processes with multiple states and transitions. It provides a visual representation of the sequential nature of the control logic, making it easier to understand and debug. SFC is often used in applications with intricate state-based control requirements, such as batch processes and system startup sequences.

There is a step by step that need to be followed in programming the PLC’S . Considering Ladder login as an example read on step by step procedure for programming PLC to know more

Considerations for Effective PLC Programming:

Documentation:

Regardless of the programming language used, thorough documentation is essential. Documenting the logic, variables, and function blocks ensures that the program is understandable and maintainable.

Testing and Simulation:

Before deploying a PLC program to control real-world processes, it is crucial to test and simulate the program. Simulation allows programmers to identify and rectify errors in a controlled environment, minimizing the risk of disruptions in the actual system.

Modularity and Reusability:

Taking advantage of modularity and reusability is especially important in large and complex systems. Function blocks and structured programming practices contribute to code that is easier to maintain and update.

Collaboration and Training:

Collaboration among programmers and effective training programs are key factors in successful PLC programming. Ensuring that the programming team is well-trained and can effectively communicate and collaborate is essential for project success.

PLC programming languages are the bridge between the industrial automation engineer’s intentions and the physical actions of machines and processes. The choice of programming language depends on the nature of the application, the expertise of the programming team, and the specific requirements of the system.

Whether using the graphical representation of Ladder Logic, the modularity of Function Block Diagrams, the flexibility of Structured Text, the efficiency of Instruction List, or the sequential representation of Sequential Function Charts, each programming language has its strengths and is suitable for different applications.

A successful PLC programmer understands the intricacies of these languages and chooses the most appropriate one for the task at hand. As industries continue to evolve and embrace new technologies, PLC programming languages will play a pivotal role in shaping the future of automation and control systems.