Electrolytic Capacitor is one of the kind of General Capacitors. With the motive of achieving the larger value of the capacitance, these capacitors were designed. In this type, the Insulating Material utilized is “Electrolytic”. The ions present in this Electrolyte will be high in concentration. The electrolyte chosen is of gel or fluid in type. It possesses ‘two terminals’ like other capacitors.

In this type of capacitor, the terminals of it are polarized. This indicates the existence of positive and negative value on the terminals. The voltage value on the terminal which is positive is always greater than that of the negative terminal Voltage. These capacitors are further classified into various types based on the variant in dielectric chosen. Further enhancements in its construction paved the way for the design of the special case of capacitors known as “Super Capacitors“.

What is Electrolytic Capacitor?

- The Electrolytic Capacitor is designed with polarity and managed to achieve a high amount of capacitance. This follows the principle of the “Forward Bias” of the Diode.

- The two terminals in it can be considered as ‘Anode’ and the ‘Cathode’.

- The voltage value at the terminal anode must be higher than that of the terminal cathode.

- These capacitors require intense care during handling. Because it can get easily overheated due to the ‘Reverse Voltages’.

- To protect it from the conditions of Over Heat a Safety Valve is placed in the capacitor.

- Some other types of Electrolytic Capacitors are designed so that it can withstand the AC Source. It means a Non-Polarized capacitor for these types also exists.

Definition of Electrolytic Capacitor

“A capacitor that is formed by the concept of anodization of the value metal to generate a high amount of capacitance value is known as Electrolytic Capacitor”.

Non- Electrolytic Capacitor

The capacitor in which it consists of “Insulating Material” called Dielectric in non-electrolytic form. These capacitors can be defined as Non-Electrolytic Capacitors. These are the generally preferred and are Non-Polarized.

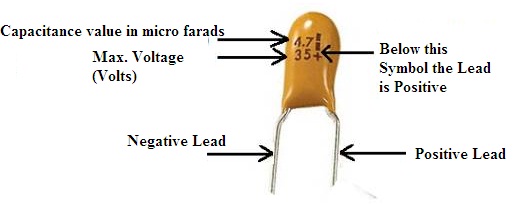

Symbol & Polarity:

As already discussed it consists of two terminals with positive and the negative Polarities. It means polarity exists in these capacitors. In terms of conduction to obtain the high-value capacitance the capacitor must in “Forward Biased.” The slight changes in the voltage from forward to reverse may affect or even damage the capacitor. Hence polarity is the important concern during the use of these capacitors in any circuit.

Electrolytic Capacitor Symbol

Construction:

It is constructed between the two plates separated with an Electrolyte. It consists of the terminals called ‘Anode’ and ‘Cathode’. These metals are covered with the ‘Oxidized Layer’. This layer is the Insulating Material of the component. Based on the type of material chosen as dielectric these are classified as

- Aluminum Electrolytic Capacitor

- Tantalum Electrolytic Capacitor

- Niobium Oxide Electrolytic Capacitor

The above is the most preferred Electrolytic Capacitor type. Let us discuss them in detail.

Aluminum Electrolytic Capacitor

- These are the capacitors that are manufactured by using the foils of aluminum on which it is coated with oxide. Upon anodization of the aluminium electrolyte it form Aluminium dioxide Al2o3 which forms the dielectric layer. The other terminal with no coating is used as Cathode.

- There are two variants in these capacitors. Firstly it is Plain type and the other is the Etched type.

Aluminum Electrolyte Capacitor

- These two capacitors are used in different applications. The plain one is preferred in providing the smoothening effect in Power Supply Circuits. The other one is preferred in the BYPASS circuits.

- The range of this capacitor is from 1 micro farad to 47000 micro farads.

- The maximum voltage range is up to 500 volts.

Tantalum Electrolytic Capacitor

- The capacitors in which the ‘Tantalum Pent Oxide’ is used as the insulating material. These capacitors can be defined as Tantalum Electrolytic Capacitors.

- Even these come under the polarized category.

- These are available in both Wet and the Dry forms.

- One terminal of it is smaller than that of the other ones. The smaller one is made up of the Manganese Dioxide.

- Upon Anodization Tantalum forms Tantalum pentoxide Ta2O3 which acts as the dielectric.

Tantalum Electrolyte Capacitor

- In comparison to aluminum capacitors, these are considered to be more stable.

- The Capacitance range is from 47 nano farads to 470 micro farads.

- The maximum range of voltage is about 50 Volts.

- These capacitors are more costly in comparison to the Aluminum Capacitors.

Niobium Oxide Electrolytic Capacitor

- Even this is made like other capacitors discussed above. The Anode of this capacitor is coated with “Niobium Monoxide”.

- These are polarized ones. It can work more efficiently with Dc Voltages.

- Upon Anodization Niobium oxide forms Niobium Pentoxide Nb2O5 which is amorphous.

Niobium Electrolyte Capacitor

The above three discussed are the types of Electrolytic Capacitors.

Advantages & Disadvantages of Electrolytic Capacitor

The advantages of these capacitors are listed as follows:

- These capacitors are used wherever their is a requirement is to achieve a high value of capacitance.

- Among all the other types tantalum capacitors are preferred for its stability reasons and are widely used one’s.

- It is useful in low-frequency applications.

The disadvantages of these capacitors are as follows:

- This capacitor must be used in combination with the non-electrolyte capacitor. This increases the size of the capacitor.

- As these capacitors possess polarity, while making connections in the circuit attention should be given.

- Electrolytic capacitors gets easily affected due to change in temperature.

The above are some of the advantages and disadvantages of these capacitors.

Applications:

The various applications of the ‘Electrolytic Capacitor‘ are as follows:

- These can be used in the various Filtering applications to reduce the content of ripple in the voltage.

- Practically, in the Audio amplification circuits to reduce the ‘hums’ in the circuit.

- In the smoothening of both the applied input and the output signals that are generated from Low Pass Filter (LPF). These capacitors are used.

Please refer to this link to know more about Filter Capacitor.

There are various applications of these capacitors. There is polarity effect and overheat conditions in these capacitors. This doesn’t go well with the signals of high frequency. It gets affected by the resistance present in it. This resistance is known as Equivalent series Resistance. The main reason of this is Power dissipation. Which is the Electrolytic Capacitor that you have used in your recent circuit?