Ceramic Capacitors are non-polarized and fixed value capacitors. In circuits where a small size of capacitor is required Ceramic capacitors comes into picture. These where intially developed in German as replacement for mica. Before 1920’s due to insulating properties of mica it was used as a dielectric material in a capacitor. Later, as there was shortage for mica a paraelectric titanium oxide was used as a dielectric which formed the Ceramic Capacitor.

The first Ceramic Capacitor was disc shaped and now it is available in different shapes and sizes. When the ceramic capacitor are layered multiple times it becomes MLCC. Depending on the shapes and sizes they are used as feed-through capacitors, electro magnetic interference supressers and even as power capacitors in transmittors.

What is Ceramic Capacitor?

The capacitors in which the CERAMIC material such a paralectric titanium oxide or ferroelectic is used as the Insulating Material or dielectric is known as the Ceramic Capacitors.

Construction :

The Ceramic Capacitor is made by making a finely grounded powder of a dielectric material which is either paraelectric material like the Titanium dioxide or ferroelectic material like the barium titanate. These materials will be added with additivies like Magnesium,Tantalum,Zinc,Zirconium (preferred for paraelectric material) and Aluminium oxide , Magnesium silicate, Aluminium silicate(preferred for ferroelectric material). The electrodes are metalized over the ceramic layer. The connecting points are connected to the electrodes. The added additives determine the permittivity of the capacitor. The capacitor made of paraelectric material and its additives will have low permittivity, linear behaviour over temperature changes and stable compared to the one made of ferroelectric material which has a high permittivity range. Based on the type of the material used the Ceramic Capacitor is classified as Class1,Class2,Class3 . The Class2 capacitors which uses ferroelectric material is more preferred nowadays compared to the Class1 capacitors which uses a paraelectric material. Class3 uses a semiconductor material which is hardly in use nowadays.

Ceramic Capacitor Types

The most widely preferred types of this Ceramic Capacitors are

- Ceramic Disc Capacitor

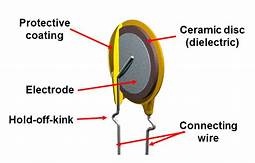

These are in the shape of Discs. It is possible to manufacture them by making the silver coating on the sides of the Discs. Where this coating is considered to be as electrodes and the disc is made of Ceramic considered to be as Dielectric.

Ceramic Disc Capacitor

- Multi-layer Ceramic Capacitor (MLCC)

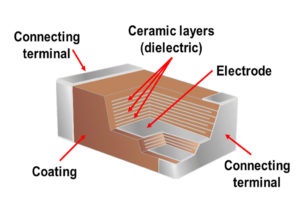

In this design “Multiple Layers of Ceramic Material” acts as Dielectric. The electrodes for this are adjusted in between the layers. These layers and the electrodes are arranged in contact with the terminals. The size and the number of layers determines the capacitivity of this capacitor.

Ceramic Capacitor (MLCC)

Ceramic Capacitor Symbol and the Polarity

Generally, like other types of capacitors called Tantalum Bead which do not possess any polarity, even these capacitors do not have any polarity. This makes it flexible in placing it in the circuit with any side.

Ceramic Capacitor symbol

Ceramic Capacitor Code

The ceramic capacitor code remains the same for its various types.

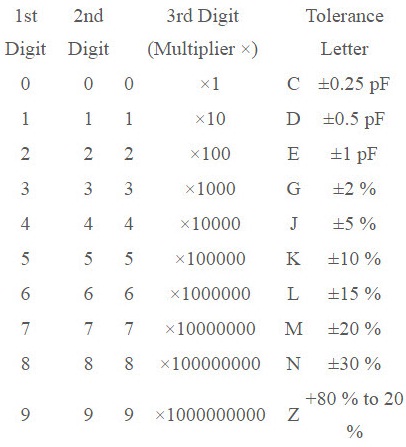

- The capacitors of this type consist of three digits followed by one alphabet.

- The initial digits that are first two, represents the value of the capacitance.

- The third number present on it represents the multiplier for the initial values.

- The overall value of this capacitance of these capacitors can be represented in terms of picofarads.

- An alphabet is also present in some capacitors. This is for the representation of Tolerance.

This is based on the “EIA” coding System.

Values :

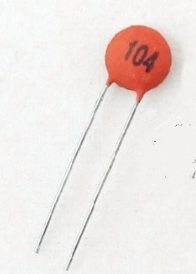

The same coding method of “EIA” is applied for the various values of the Ceramic Capacitors. For example, let us consider the capacitor printed on it with the value as 104.

Ceramic Capacitor 104

- In this, the first initial two digits represent its value in the capacitance of pico-farads.

- The last digit printed is 4 it indicates that it is a multiplier of the value (10^4).

- Finally, the value of the capacitance can be generated as, 10*10^4= 10*10000 = 100000 picofarads.

If there is no last number present in that case the initial two numbers represent the overall value of capacitance without any Multiplier in it.

Capacitor Codes Based on EIA

Advantages and Disadvantages of Ceramic Capacitor

The various advantages of the ceramic capacitor are as follows:

- The physical structure of this capacitor is a compact one.

- Because of the non-polarized nature, it is well suited for application of AC signals.

- These capacitors perform better in signal interference suppression like Radio frequency suppression, electromagnectic interference suppression.

- This cost of this capacitor is not high and at the same time this capactiors can withstand upto 100v.

The disadvantages of using these capacitors are as follows:

- These capacitors consist of the capacitance value of fewer than one micro-farads.

- Sometimes these components are responsible to generate the Microphonic effect in the circuits.

- It cannot tolerate high voltages. Because the dielectric present in it can easily get affected by it. This results in the breakdown.

Applications :

There exist various applications for these kinds of capacitors. Some of them are listed as follows:

- In the Transmitter stations in the Resonant circuits, these capacitors are used because of their “high power applications”.

- Even these capacitors are preferred as General Purpose Capacitors. The reason behind this is, it is a Non-Polarized Capacitor.

- To maintain the minimum value of RF Noise these are placed across the Brush Dc Motors.

- In the converters of DC-DC, these capacitors are preferred.

- SMD types of ceramic capacitors are mainly used in the PCB’s.

Please refer to this link to know more about Mica Capacitor & Tantalum Capacitor.

There are various types in the Ceramic Capacitors. Above all the MLCC variant is the most prominent one. As per the discussion above it clearly states the basic steps of involvement in its construction. It is very popular because of its non-polarized nature. Hence these capacitors can be connected with any side because of its nature. Have you come through any other capacitor which possesses non-polarized type?