A Programmable Logic Controller or a PLC a computer-type device, mainly used for controlling different equipment in an industrial facility like conveyor systems, utility plants, chemical processing, food processing machinery, a batch control application, auto assembly lines, etc. In a PLC system, the wiring between different devices is replaced by PLC. There are various brands of PLCs like Mitsubishi, Allen Bradley, Siemens, Omron, etc. But Allen Bradley PLCs are one of the top manufacturers around the world. This is the umbrella company owned by Rockwell Automation. This company simply designs, installs, develops & supports its own line of programmable logic controllers. The most frequently known Allen Bradley PLC families are; CompactLogix, MicroLogix & ControlLogix. So this article discusses an overview of Allen Bradley PLC – working with applications.

What is Allen Bradley PLC?

The Allen-Bradley programmable logic controller is one type of PLC that ranges from small to large & even micro applications. These programmable logic controllers were invented by Odo Josef Struger who is the father of the PLC. He contributed many ideas while inventing these PLCs over a period of time from 1958 to 1960. Allen-Bradley is turned into a major PLC manufacturer in the USA. Allen Bradley provides various types of controllers in different sizes for your specific requirements. These PLCs help you in meeting simply complex application requirements from the original PLCs to the scalable, information-enabled & multi-disciplined PACs (programmable automation controllers).

Allen Bradley PLC

Allen Bradley PLC Specifications

The specifications of Allen Bradley PLC are given below.

- The input voltage of PLCs ranges from 100 to 120V AC, 24V DC or 200 to 240V AC.

- Maximum Input-power is 27 VA, 40 VA, 68 VA, 70 VA, 80 VA, or 82 VA.

- Communication options like EtherNet/IP, DH-485 & DeviceNet.

- Memory module used for program or data backup by uploading & downloading programs.

- RTC for time-scheduling to control activities & applications.

- Expansive I/O & communication options.

- 24 or 40 in-built I/O with the capability to include up to 96 I/O.

- They have four interrupt & latching inputs.

- 20k Hz – PWM or Pulse Train Output.

- 20k Hz – high-speed counter.

- Inbuilt potentiometers – 2.

Allen Bradley PLC Architecture

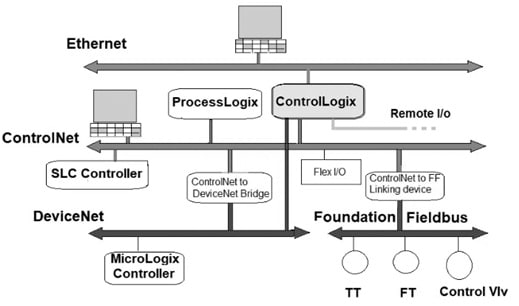

Allen Bradley PLC architecture is shown below which includes different blocks like ControlLogix, ControlNet, DeviceNet, Ethernet, SLC Controller, Remote I/O, Serial, and field bus network where each block is discussed below. Allen Bradley PLC provides a high-performance control platform for various kinds of control that performs the process, sequential, drive otherwise motion control in any arrangement through this single platform. This PLC is a very flexible platform, so it allows various networks, processors, and Input/output to be mixed with no limitations. Whenever the application requirement increases, one can simply use Net Link architecture for controlling information across Ethernet, DeviceNet & Foundation Fieldbus.

Allen Bradley PLC Architecture

ControlLogix Controller

ControlLogix controller simply stores design data for each I/O module, so it can be a limited or a remote I/O. This controller simply performs the ladder motion commands.

ControlNet Controller

This controller simply communicates across the backplane through communication interface modules for monitoring & controlling I/O on DeviceNet, ControlNet, Universal Remote I/O networks & also for monitoring foundation field bus data. A backplane is a common bus that is shared through different subsystems. This bus simply permits a system to allocate both power & data.

For interfacing the backplane through ControlNet, Ethernet, Universal Remote I/O networks & RS232 networks, a separate communication module is available. A controller communes with control modules within local I/Os & remote I/O across DeviceNet, ControlNet & Universal Control I/O. So, single or many controllers are arranged on a single control logic chassis which is capable of addressing a large no. of I/Os.

ControlNet Communication module is an open & high-speed network mainly used for transmitting data. This communication module simply provides real-time control and message services for peer communication. This module simply links ControlNet links for routing messages above other networks like Ethernet, ControlNet.etc. It simply supports programming, device configuration & peer to peer messaging. ControlNet is connected through PCs, I/O modules, operator interfacing devices & controllers.

DeviceNet

DeviceNet in this architecture is a low-level and open connection link between simple and process measurement devices such as actuators & sensors. The DeviceNet simply provides interoperability and cost-effective wiring as compared to fixed I/O wiring because devices should not be connected straight to programmable controllers. DeviceNet simply supports device-level diagnostics and connects to various devices of vendors.

Ethernet Network

An Ethernet network is a LAN mainly designed for the high-speed data exchange between computers & associated devices. This network simply provides enterprise-wise systems access to plant floor data and it transfers large data files.

SLC Controller

The SLC controller or Small Logic Controller is a control platform. It is a chassis-based, I/O module, a modular family of PLCs, and peripheral devices. The SLC 500 family simply delivers a powerful solution for distributed industrial control & mid-range separate control with various processor choices, an extensive range of communication configurations, more memory capacities & various power supply options, Additionally, this controller is programmed with RSLogix 500 Ladder Logic programming software where this software provides a power database editor, flexible editors, pint & click I/O configuration, superior diagnostic & troubleshooting tools to increase productivity.

Remote Input/Output Network:

Universal remote I/O network simply supports various Allen Bradley & third-party devices.

Serial Network:

The serial port supports the DP1 protocol on the serial links to commune with other devices.

Fieldbus Network:

The Fieldbus network is a separate network that is mainly designed for handling various process automation applications. These networks can connect directly low-level devices to plant floor controllers. This network simply interconnects controllers through sensors and actuators.

Working

The Allen Bradley PLC is a special computer that works through programming for controlling certain processes within industries like Steel, petroleum, or automotive. So in industrial automation, Allen Bradley PLC programming is an extremely preferred skill, thus it allows one to make a set of instructions to control various devices, machinery & total manufacturing plants.

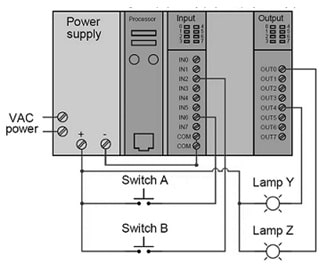

Allen Bradley PLC Circuit Diagram

The Allen Bradley PLC circuit is shown below. This circuit is built with an Allen Bradley PLC, two switches like switch A & switch B, and Lamps Y &Z. Make the connections of PLC, switches, and Lamps as per the circuit shown below.

Allen Bradley PLC Circuit Diagram

Allen-Bradley model PLC is connected to a set of pushbutton switches & light bulbs as shown in the above circuit. Examine the Allen-Bradley PLC to determine the required switch conditions for energizing lamps Y & Z.

The working of this circuit is very simple which follows as; if switch ‘B’ is pressed and switch A is released then lamp Z will be energized. Similarly, if switch ‘A’ is pressed and switch B is released then lamp ‘Y’ will be energized.

Allen Bradley PLC Types

There are different kinds of Allen Bradley PLCs available in the market like micro and nano control systems, small control, and large control systems. Each type of control system is again divided into different types.

Micro and Nano PLCs

These types of PLCs simply provide cost-effective solutions to the basic control needs of simple machines which range from relay replacement to simple control timing & logic. These PLCs are available in different types like Pico controller, micro800, and micro logix.

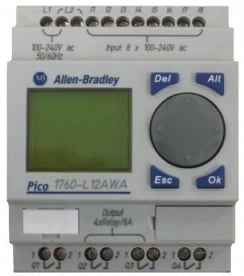

Pico Controller

The PICO controller is a programmable logic control device that is used for the automatic dispensing process control in viscous fluid media. This type of PLC is used to perform different operations like timing, simple logic, counting, RTC or real-time clock, etc.

PICO Controller

This type of PLC is simple and small, flexible, counting, performing logic, operating system & clock time. It is simply programmed and operated with programming software like PicoSoft creating, documenting, storing, etc. This programming simply provides additional functionality & ease of programming for PicoGFX controlling. This PLC is available in various configurations which range from 12 to 20 in-built DI/DO, analog inputs, ac/dc power & an LCD display.

This PLC can also be extended to 40 through 4 soft input keys so two analog inputs are simply given through 0 to 10 a VDC for better efficiency. A total of 16 timers & counters are placed to check the device through complete four RTC instructions.

Micro800 Controller

The Micro800 PLC simply provides a robust & scalable micro control solution, especially for small to huge standalone machine applications. These are available in different form factors and these PLCs are designed with flexibility & customization. The Micro800 family simply shares a programming environment, plug-ins & accessories that permit machine designers to personalize the controller for precise capabilities.

Micro800 Allen Bradley PLC

Micrologix Controller

The MicroLogix 1000 and MicroLogix 1400 PLCs are used to provide factory floor networking & decrease production troubles. MicroLogix 1000 PLC is perfect for various applications which range from SCADA, water, or wastewater for material handling & packaging. These PLCs have some features like a faster high-speed counter, a higher I/O count, pulse train output, improved network capabilities & rear light on the LCD panel.

Micrologix PLC

Small Control Systems

Small control systems provide the flexibility & features that you require without the overhead of larger systems. These PLCs are available in different types which are used in mid-range applications like SLC 500 controller, smart gaurd600, compact gaurdlogic safety controller, and compact logix controller which are discussed below.

SLC 500 Controller

The Allen-Bradley SLC 500 controller or small logic controller & is a chassis-based family of PLCs, analog, discrete, I/O & peripheral devices. This PLC family simply delivers power as well as flexibility through a broad range of communication configurations, memory options, and features. The main features of this PLC include affordable, powerful, modularity, advanced instruction set, windows programming software, password protection, in-built RS-232 or 422 or 423 communication port, LED status & low battery indicators, operating temperature ranges from 0 to 60°C, etc.

Allen Bradley SLC 500 Controller

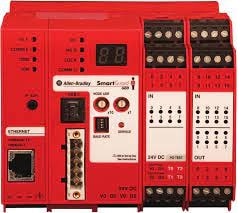

Smart Guard 600 Controller

SmartGuard 600 controller is available with security features, safety-rated inputs -16, safety-rated outputs-8, pulse test sources -4 & an optional EtherNet/IP port. This controller has a DeviceNet connection for supporting both typical CIP & CIP security. The DeviceNet connection in this controller simply supports both CIP and standard safety communication. The programming and configuration can be accomplished through an inbuilt USB port. These PLCs are small, gainful intelligent controllers which can perform security interlocking in between GuardLogix (or) other SmartGuard security controllers.

Allen Bradley Smartgaurd 600 PLC

Compact Gaurdlogic PLC

The compact guard logic PLC simply brings jointly the typical control functionality of the Logix control platform. This PLC simply controls up to 8 axes of motion & simply supports the utilization of compact block guard I/O, and point guard I/O on Ethernet/IP. This PLC is ideal mainly for mid-range of applications. These PLCs simply provide high performance, improved productivity, increased capacity & improved safety to meet the rising demands of smart machines.

Compact Gaurdlogic PLC

Compact Logix Controller

This PLC is a Logix controller system extensively utilized in small & medium industrial applications. These control systems are mainly used to control different applications on the machine level. This system is mainly designed for providing a Logix solution, especially for mid-size and small applications.

These types of controllers utilize a common user-friendly development environment. The tight integration in between the controller, programming software & I/O modules decreases cost & development time at commissioning & throughout normal operation.

Allen Bradley Compact Logix Controller

Large Control System

Large control systems simply fit in most demanding applications which need high-performance-based communications, motion control & I/O for up to 256 axes. These PLCs are available in different types like PLC5 controller, GaurdLogix controller, SoftLogix controller & ControlLogix controller.

PLC5 Controller

The PLC5 controller is a programmable controller that stands in the middle of a control architecture that brings existing as well as future systems together through different networks like ControlNet, EtherNet/IP, DeviceNet & provides connectivity between ControlLogix, MicroLogix & SLC 500 controllers.

Allen Bradley PLC5 Controller

GuardLogix Controller

A GuardLogix controller is a ControlLogix processor that is mainly utilized in safety control. The GuardLogix system is available with a dual-processor solution and it uses a safety partner and a primary controller. A GuardLogix L6 controller is used with a 1756-LSP safety partner and a GuardLogix L7 controller is used with a 1756-L7SP safety partner to Cat. 4/PLe & Achieve SIL 3. The major benefit is a single project standards & safety are combined jointly. It doesn’t need any user setup because the safety partner is a part of the system & is configured automatically.

Allen Bradley GuardLogix Controller

SoftLogic Controller

Softlogic controller PLC is one type of logic platform. This is a soft control solution that works in Windows XP or Microsoft windows 2000. This type of PLC mainly includes a stand-alone, single computer with its networked devices.

SoftLogic Controller

ControlLogix Controller

This type of PLC simply provides a control platform with high performance for various types of control. In any combination with this single platform, we can easily perform process, sequential, motion or drive control because this control platform is modular, so we can modify and design it very efficiently.

ControlLogix controller PLC monitors & controls I/O across the backplane of ControlLogix & above I/O links. This controller communicates above ControlNet, EtherNet/IP, DeviceNet, Remote I/O, RS-232-C & DH+™ networks as well as several third-party process & device networks.

Allen Bradley ControlLogix Controller

Advantages

The advantages of Allen Bradley PLC include the following.

- Allen-Bradley programmable logic controllers are more user-friendly.

- These are very easy to program.

- These are faster & very simple to debug as compared to Siemens PLCs.

- Allen Bradley PLC is widely used because of its advantages.

- Initiative & very easy to use.

- These PLCs have a large number of I/O points.

- Maintenance cost is low.

- Its controlling is very easy.

- This type of PLC can be used in medium, small & large controlling-based applications.

- Its construction is simple.

- They have a longer lifetime.

- Not expensive for the big operation

- These are capable of online troubleshooting.

The disadvantages of Allen Bradley PLC include the following.

- Allen Bradley PLCs are complex to maintain & program.

- They have limited processing power.

- The expandability is limited so they are not capable of expanding or modifying to perform the latest tasks.

- These PLCs need training.

- It depends on the programming.

- If we do not use them properly, they can cause a breakdown.

Applications

The applications of Allen Bradley PLC include the following.

- It is mainly used for the large control system.

- These types of programming logic controllers are used in batching, processing & in motion control systems.

- They are used in your electrical control otherwise automation solution to support a variety of I/O modules, drives, portable data collectors, sensors, servo systems, & programmable controllers.

- Allen Bradley PLC Programming is extremely required in industrial automation.

- These are used in batching, processing & in a motion control system.

- It is used in small, large & even micro applications.

- These are extensively used in current industrial automation to control machinery and in industries like food and beverage production, packaging, printing & pharmaceutical.

Please refer to this link to know more about PLC Programming Languages.

Thus, this is an overview of Allen Bradley PLC – working with applications. Generally, PLCs are flexible & robust and are used in several applications like automation, instruments, building equipment, power transform devices, meters & low voltage devices. Here is a question for you, what is SCADA?