The manufacturing industries are incorporating automated technology and making it is very significant for the production and development. The Industrial automation can make the production workers’ lives very easier & helps in increasing the productivity of corporation. One of the important one which helps in all the automation process is sensor. There are humpty number of sensor available in the market nowadays. One of the among. them is the photoelectric sensors are used in industries to help the workers in achieving a variety list of tasks in the production department. This article provides brief information on a photoelectric sensor.

What is a Photoelectric Sensor?

A photoelectric sensor is one type of device used to detect a difference in the level of light obtained from the source of light. This type of sensor is made up of a source of light, an amplifier, a signal converter & an output. These sensors detect different objects, the presence/absence of an object, changes within surface conditions, and measure the distance between an object & a point & other devices with different optical properties. So, these sensors have become a very famous choice in industrial automation because they provide reliable & quick results without touching the object physically. The photoelectric sensor symbol is shown below.

Photoelectric Sensor Working Principle

The working principle of a photoelectric sensor is to change the intensity of light into electrical signals by using a photoelectric component like a conversion element. This sensor is composed of three main parts transmitter, receiver & detection circuit.

The transmitter in this sensor emits a light ray to the object & the emitted light ray is usually a semiconductor light source like an LED, a laser diode & an IR diode. The ray is emitted constantly otherwise changes the pulse width to achieve it.

The receiver commonly includes a photodiode, a photocell, and a phototransistor. Ahead of the receiver, optical components are installed like lens & aperture. At the back of the receiver, a detection circuit is used where this circuit filter outs the effective signal & make appropriate actions.

Generally, this sensor includes mainly an Emitter used for emitting a beam & a Receiver used for getting light. Once emitted light is reflected/ interrupted through the sensing object, then it changes the light that reaches the Receiver. So this receiver will detect the change & changes it to an electrical signal.

Specifications

The photoelectric sensor specifications are discussed below which describe its performance.

- The detecting range of the sensor mainly depends on the highest distance for which the signal is constant.

- Response time specifies the time delay between the object moving into the detection zone & the production of the discovery signal.

The measurement of the position ‘window’ simply decides the width of the sensor’s linear region. A sensor has a 10 cm window when it measures between 14 & 24 cm.

Photoelectric Sensor Vs Ultrasonic Sensor

The difference between the photoelectric sensor and ultrasonic sensors includes the following.

|

Photoelectric Sensor |

Ultrasonic Sensor |

| A photoelectric sensor is very helpful in determining the distance, and presence/ absence of an object through a light Tx & a photoelectric receiver. | An ultrasonic sensor emits ultrasonic sound waves to measure the distance of an object & changes the reflected sound to an electrical signal. |

| A photoelectric sensor is influenced by its colors while detecting an object. | The ultrasonic sensor is not influenced by its colors while detecting an object. |

| This sensor uses IR light or visible red light to measure the distance between a point & an object. | This sensor uses ultrasonic signals to measure distance. |

| These sensors detect very small objects. | This sensor can detect nearly every object. |

Photoelectric Sensor Vs Proximity Sensor

The differences between photoelectric sensors Vs proximity sensors include the following.

|

Photoelectric Sensor |

Proximity Sensor |

| This sensor uses light to detect an object without physical contact.

|

This sensor utilizes an electromagnetic field to detect an object without physical contact. After that, it changes this data into an electrical signal. |

| The sensing range of this sensor is long as compared to proximity sensors like 800 ft. or 243.8 m. | The sensing range of this sensor is short as compared to a photoelectric sensor like 1 in. or 25.44 mm. |

| This sensor responds in microseconds. | The proximity sensor has a longer response time as compared to the photoelectric sensor in milliseconds. |

| This sensor notices invisible markings on products. | This sensor cannot notice the markings. |

| The price of this sensor is higher compared to proximity sensors because it has different types & several detecting methods. | The price of this sensor is lower compared to the photoelectric sensor. |

| The size of this sensor is smaller. | As compared to the photoelectric sensor, the size of this sensor is bigger |

| This sensor detects different colors. | This sensor cannot detect different colors. |

| If the lens surface of this sensor is covered with dirt or dust then the transmission of light is obstructed. So the detection of an object is not possible. | This sensor does not have this trouble. |

Photoelectric Sensor Types

There are three types of photoelectric sensors available in the market through-beam, retro-reflective & diffuse reflection sensors.

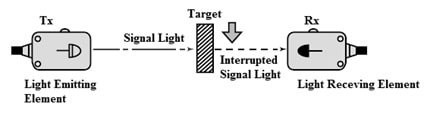

Through-beam Sensor

Through-beam sensors transmit the light beam only in a single direction. In this sensor, both the sender & receiver are arranged in different housings & there is no return of the light. This kind of sensor is common as compared to retro-reflective type sensors because both the transmitter & receiver of this sensor are contained within a single unit. This sensor detects objects once it interrupts the light ray in between the two sensors.

Through Beam Type Sensor

The main benefits of using this thru-beam sensor are, that it is a very accurate type and its detecting range is high. So these sensors are the best choice to use in a dirty environment also.

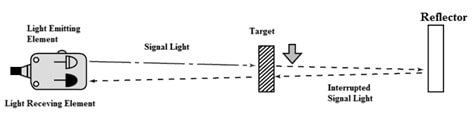

Retro Reflective Sensor

In these types of sensors, both the transmitter & receiver are arranged within a single unit. The light ray is transmitted to the reflector and it will be returned back to the light receiving element. Once a target is available in between these two, then the light is interrupted. These sensors are used on a conveyor belt to detect objects.

Retroreflective Type

This sensor is very affordable and less accurate as compared to thru-beam sensors. These sensors are suitable to use when transparent or clear products need to be detected.

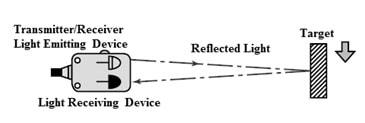

Diffuse Reflection Sensors

In these types of sensors, the transmitter & receiver are arranged within a single housing. Not like the retro-reflective, this sensor uses the target object like the reflector rather than using an installed reflector. When selecting this sensor, the detecting range as well as the reflection angle must be considered. This sensor detects objects once the light beam is transmitted in the direction of the target & is reflected back by the target toward the sensor.

Diffuse Reflection Sensor

These sensors are very easy to install because everything is built-in this device. These are less accurate as compared to thru-beam & retroreflective sensors once used to detect position. Additionally, these sensors are affected by texture, color, the position of incidents, dirty environments, characteristics of the target, etc.

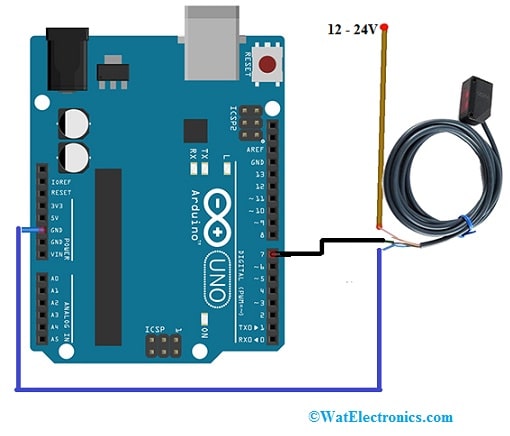

Photoelectric Sensor Interfacing with Arduino

We know that a photoelectric sensor is mainly used for detecting objects & obstacles at a distance of 5-100 mm. The photoelectric sensor used in this interfacing is OMRAN Company which has an LED. This LED is turned ON/OFF based on the detection of obstacles. When this sensor detects any obstacle then the output is HIGH otherwise LOW whenever there is no obstacle.

The pinout of this photoelectric sensor is shown below. This sensor includes three wires which are discussed below.

Photoelectric Sensor Pinout

- VCC: It is a brown color wire used to provide power supply from 12 to 24V.

- GND: It is a blue color wire used for grounding purposes.

- DATA: It is a black color wire which is a sensor output.

The required components for interfacing a photoelectric sensor with an Arduino mainly include

- Arduino UNO R3,

- OMRON Photoelectric sensor,

- jumper wires, and

- Arduino IDE.

The photoelectric sensor circuit diagram with Arduino is shown below. Give the connections as per the circuit shown below.

Photoelectric Sensor Interfacing with Arduino

Upload the below code to the Arduino board and open Serial Monitor.

void setup()

{

pinMode(7, INPUT); // sets the digital pin 7 as input

Serial.begin(9600);

}

void loop()

{

if(digitalRead(7))

Serial.println(“Object Detected”);

else

Serial.println(“No Object”);

delay(1000);

}

In the above Arduino code, first, we have to read the output of the sensor for each second. If the sensor output is HIGH, then an obstacle is detected. Similarly, if the sensor output is LOW, then there is no obstacle. For every few seconds, we need to place the hand ahead of the sensor to observe its performance.

Advantages and Disadvantages

The advantages of the photoelectric sensor include the following.

- By using these sensors, detecting all types of materials is possible.

- These sensors have a longer life.

- These are very reliable & their detecting range is long.

- Its response time is very fast.

- These sensors are not expensive.

- Through-beam photoelectric sensors have stable readings across a broad range of operational distances.

- These sensors have the capability to sense different objects within a broad range of materials, positions & colors.

- The retroreflective sensors advantages mainly include: they have a broad range of operating distances, and their installation and adjustment are easy.

- It is not affected mainly through movement path or object color.

- These sensors detect transparent or translucent objects because the light ray travels twice throughout the object.

- Diffusion sensors’ benefits are; that these sensors are easy to adjust and mount once the transmitter & receiver are housed again within a similar module.

The disadvantages of the photoelectric sensor include the following.

- The sensing range of this sensor is simply affected because of the reflectivity & color of the object.

- Thru beam-type sensor needs a transmitter & receiver at two different locations.

- The retroreflective sensor needs a reflector also to Tx/Rx so that system installation will become complex.

- The installation process of the Through-beam sensor is more complex because the wiring is necessary at both ends.

- Retroreflective sensors have a potential dead region at an extremely short range & they cannot be utilized to detect extremely reflective objects.

- The diffuse-reflective sensors’ reliability readings can be impacted easily by the color, shape, distance & material of an object and also by different environmental conditions.

Applications

The applications of the photoelectric sensors include the following.

- These sensors are used in many industries like automotive, food and beverage, doors and gates, machine engineering, material handling, pharmaceutical industries, etc.

- These sensors are mainly used for converting a light signal into an electrical signal. By using the emitted light from a transmitter, this sensor detects objects simply from far away.

- Photoelectric sensors are used in the logistics industry.

- These are used in elevators & automatic doors.

- These are used for detecting objects otherwise an object’s direction in a production.

- These are mainly used for counting devices.

- These sensors are also used to stop an automatic closing door.

- These sensors are used to detect device size & spot errors, installation bag seals, object height, etc.

- It detects automobiles within parking areas and also detects whether crystal clear bottles are filled or not.

- Photoelectric sensor examples are; checking different objects on conveyors/ production lines, counting objects, colors detecting, distance measuring, automatic doors, logistics & materials handling, and bigger areas monitoring for objects through light grids.

Thus, this is all about an overview of a photoelectric sensor – working with applications. The features of these sensors mainly include high resolution, quick response time, simple adjustment, identification of color, non-contact detecting, long-distance detecting, etc. Here is a question for you, Photoelectric sensor also called?