In nanotechnology, the nanosensor is used as a sensing device to measure/detect/sense the chemical and physical properties of matter or nanoparticles at the nanoscale of less than 100 nm. These are used for changing the applications and properties of the materials. These are nanodevices that observe physical quantities and convert them into signals that can be detected and analyzed.

Nanosensors are used in medicine, pollution control, pathogen detection, and process monitoring in manufacturing and transportation systems. This technology identifies the particular cells at the molecular level to deliver medicines and monitor the development of specific body parts by measuring physical properties such as volume, motion, concentration, speed, gravity, magnetic force, pressure temperature, and electricity. This article gives a brief description of a nanosensor.

How Do Nanosensors Works?

The working of nanosensors is similar to the sensor that is used to detect and monitor the presence of chemicals, nanoparticles, and physical parameters like temperature, force, flow, etc at the nanoscale. They are either mechanical or chemical sensors widely used in medical applications, sensing water quality, food, etc. These are the sensitive materials used for the transmission of physical, chemical, and biological data of nanoparticles and recognize the molecules.

These are smaller in size and weight. And also available in larger devices to monitor and measure the unique qualities of nanoparticles at the nanoscale. These are highly sensitive devices. These are used in various applications such as sensing metabolic activities, plant synthetics, storing and computing data, sensing environmental conditions, energy supply, etc. They work efficiently and effectively at the nano level.

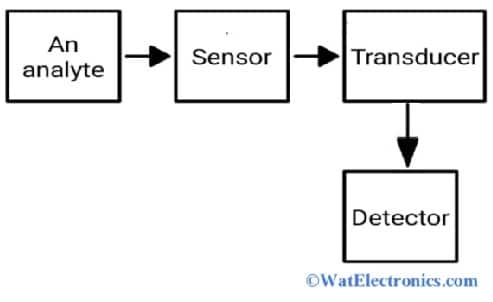

Nanosensors can detect and monitor electrical, optical, biomedical, and mechanical signals. The basic components of nanosensors are an analyte, sensor, transducer, detector, and the feedback path from the detector to the sensor block (if necessary). These sensors operate by monitoring the electrical changes in the sensor material and are capable of measuring single molecule levels.

Block Diagram of Nanosensor

Analyte and Sensor: An analyte is diffused from the solution onto the sensor surface and reacts efficiently and effectively.

Transducer: This can change the physical and chemical properties of the transducer. This results in a change in electronic or optical properties of the transducer surface and converted into electrical signals. Because the transducer converts one form of signal/energy into another.

Detector: The electrical signal obtained by the transducer is detected by the detector.

For example, When ammonia molecules are present in a carbon nanotube sensor, they react with water vapor to donate electrons, making the carbon nanotube more conductive. Conversely, the presence of nitrogen dioxide molecules removes electrons from the nanotubes, making the carbon nanotubes less conductive.

The different working principles are used in different nanosensors for signal detection on the nanoscale. For example, a change in electrical signal distribution is detected by the electro-chemical nanosensors; a change in intensity of light is detected by the optical nanosensors; a change in mass is determined by the piezoelectric nanosensors, etc.

Nanosensor Types

The different nanosensor types are given below based on the detection of signals.

Optical Nanosensors

These types of sensors are used for analytical purposes, to monitor and detect biological or chemical processes and convert the information into signals for important data. These are further divided into 2 types, are

- Proximity Nanosensors

- Ambient Light Nanosensors

Biological Nanosensors

These are used for bio-molecular processes like interactions of DNA, antigen or antibodies, enzymatic or for communication of cellular processes. These are further divided into 3 types. They are,

- Enzymatic interaction nanosensor

- Antibody Or antigen interaction nanosensor

- DNS interaction nanosensor.

Chemical Nanosensors

These are used to determine the identity or concentration of a chemical substance. These are further divided into 2 types. They are,

- Molecular concentration nanosensors

- Chemical composition type nanosensors.

Physical/Mechanical Nanosensors

These are used to monitor and measure the properties of material like force, pressure, displacement, temperature, pressure, and mass. These are further divided into 4 types. They are,

- Pressure type nanosensors

- Mass-type nanosensors

- Displacement type nanosensors

- Force type nanosensors.

- Temperature nanosensors

- Flow nanosensors.

Nanosensor Circuit Diagram

A proximity nanosensor is one of the types of optical nanosensors, which are designed to detect the presence of an object or to detect a moment in several mobiles, industrial, electronic appliances, and retail automation. It can detect the presence of closer objects without any physical contact. Examples: the paper condition in a printer, and mobile phone screen brightness detection to save the battery life.

There are 4 types of proximity sensors. They are,

- Inductive proximity sensor

- Capacitive proximity sensor

- Magnetic proximity sensor.

- Infrared proximity sensor

The proximity sensors can detect iron and non-iron metal objects using high-frequency oscillation techniques. And also capacitive techniques are used in this sensor to detect non-metal objects.

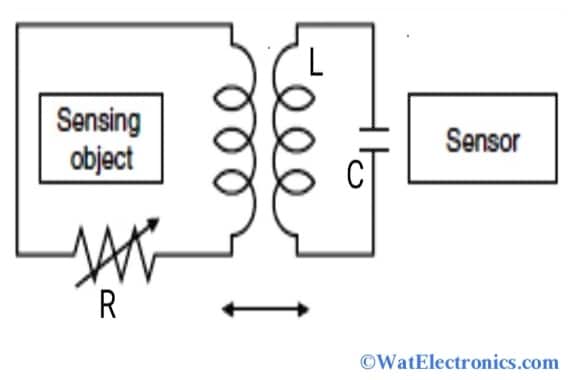

Consider the inductive proximity nanosensor circuit diagram as shown in the figure below.

Inductive proximity sensors can detect magnetic field leakage due to eddy currents generated by an external magnetic field on a conductive surface. An alternating magnetic field is created in the detector coil and changes in impedance due to eddy currents produced by metal objects are detected.

Proximity Nanosensor Circuit Diagram

From the above circuit diagram, the sensor and the sensing object together appear like a transformer coupled connection. This connection is replaced by the change in impedance between the sensor and the sensing object. The change in impedance is observed as a change in resistance, which can be determined by the variable resistor connected in series with the sensing object.

The other techniques include an aluminum detecting sensor, which detects the phase-frequency component, and an all-metal sensor that uses an active coil to detect only the changing impedance component. There are also pulse sensors that generate eddy currents in the form of pulses and detect changes in time in eddy currents with induced voltage in the coil.

Nanosensor Fabrication Techniques

Nanosensors are designed using 3 types of fabrication techniques such as top-down, bottom-up, and self-assembling.

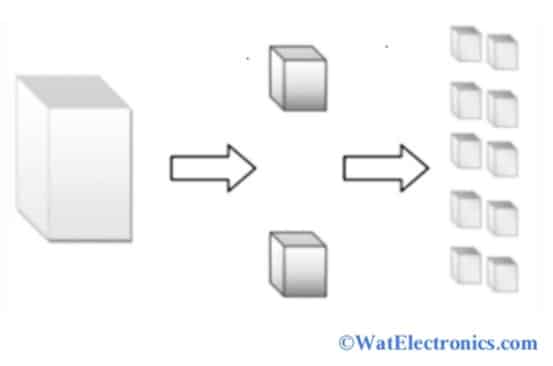

Top-down Fabrication Technique

It is also known as sculpting. To achieve the desired shape, the base material is disintegrated. This process is done either mechanically using UV-light, electron beams, X-rays Or chemically using acids. This technique is employed in computer chip manufacturing. A lithographic patterning such as nanoscale printing, moulding, and stamping can be carried out using this method. The top-down process is shown in the figure below.

Top-down Fabrication

From the above figure, the bulk material is disintegrated from top to down to convert into powdered material. And then it is divided into nanostructures as shown above. This method is applicable at the microscale but not at nanoscale dimensions.

A planar technique is involved in this method. That means structures are generated by adding and subtracting the patterned layers. Hence, it is tough to build 3D objects.

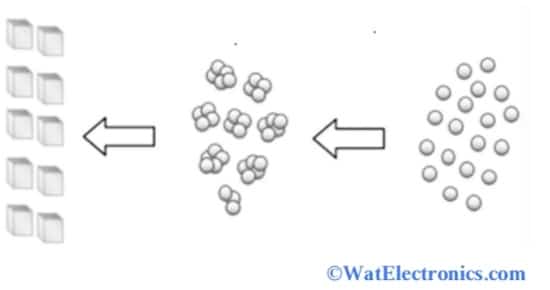

Bottom-Up Fabrication Technique

It is also known as constructing. For example, the building of a brick house is similar to this method. The below figure helps to understand the bottom-up fabrication method. To achieve the specified or desired nanostructure, the molecules and atoms are kept from bottom to up.

Bottom-up Fabrication

From the above figure, the atoms are placed from bottom to up to form clusters, which are groups of atoms. And then converted into nanostructures very easily. This is a time-consuming technique. Hence self-assembly is introduced.

Self-assembling Fabrication Technique

The nanostructures take advantage of the ability of particular polymers and molecules to self-assemble into 2D/3D nanostructures. The specific structures and types of molecules are used to create different characteristics and specifications. This method is inspired by biological systems, in which nature uses chemical forces to create almost all the structures necessary for life. The researchers desired to replicate this ability. For example, quantum dots growth, DNA-assisted assembly, etc.

How Nanosensors are used in Optical and Agriculture:

Nanosensors in Optical:

Optical nanosensors are designed and developed to use fluorescent sensitivity for quantitative measurements of the intracellular environment with devices small enough to fit inside living cells with minimal physical disruption.

The advantages of using optical nanosensors compared to widely used fluorescent dye-based methods are the protection of the sensory component from interfering species in the intracellular environment; and the protection of the intracellular environment from the toxic effects of the sensory component.

Fiber-Optic nanosensors were initially designed as scopes (scanning probes) for Near-Field Optical Microscopy, which used detectors or light sources with smaller wavelengths than the light wavelength for increased spatial resolution of approximately 12nm.

By using this fiber-optic nanoprobe (used as a localized light source), the pattern images can be reconstructed from a raster scan done in illumination mode.

Near-Field Microscopy with a very high spatial resolution (12 nm nearly) is used in several applications such as NF-SERS (Near-Field Surface Enhanced Raman Spectroscopy) for dye-labeled DNA and single dye molecules measurements with a 100 nm resolution.

Detection of single molecules and imaging methods using nanofibers, which are capable of investigating biochemical reactions and biological systems, which can lead to significant applications in the medical field.

A Biosensor is a Biological Recognition System with a transducer. It uses several transduction methods such as Electrochemical Detection Optical Detection, Mass Detection, and other methods including Magnetic and Voltaic.

Nanosensors in Agriculture

Nanosensors play an important role in the advancement of agriculture to facilitate real-time monitoring of field and crop conditions, pest attacks, environmental stressors, and plant diseases.

The application of nanosensors converts the practices of conventional agriculture into smart agriculture, which is energy efficient, environmentally friendly, and sustainable.

- The practices of smart agriculture include nanoformulation-based pesticidal delivery systems or fertilizers that increase the dispersion and wetness of nutrients.

- Nano detectors for fertilizer or pesticide precipitates.

- Remote sensing monitoring systems to monitor plant disease, crop production, and crop growth.

Used to detect soil humidity, pesticide residues, crop pests, and nutrient requirements.

Nanosensors in smart agriculture are highly sensitive with a low limit of detection.

For pesticide detection, nanosensors used different metal nanomaterials such as gold nanoparticles, carbon nanotubes, quantum dots, and several nanocomposites with polymers.

The benefits of using nanosensors in agriculture include a high surface volume ratio, quick response (within seconds), more stable, reliable results, smaller amounts of detection, super fast electron transfer, and practicable in different matrices.

Nanobiosensors are developed to detect the soil that has phosphorus-containing amino acid type herbicide. These biosensors use nanofilms with pencil graphite electrodes and analysed glyphosate and glufosinate in detection limit.

These days, nanosensors are used for the estimation of fertilizer in a growing field, accurate information about fertilizer requirements, pest control, odors creating bacteria, and detecting urea. This results in reducing the cost to farmers and saves unused fertilizers.

Finally, we can conclude that the application of nanosensors in agriculture includes soil quality, soil fertility, microbiological environment, seed viability, safety, irrigation, precision agriculture, detection of residual pesticide, fertilizer, toxins, crop pests detection, and plant pathological detection.

Nanosensor Techniques used to Detect the Pesticide or Fertilizer Residues:

In recent decades, many problems have arisen that have created an urgent need to ensure global food security. The process of increasing food production has presented agricultural ecosystems with many challenges, including the persistence of various pesticide/fertilizer residues adversely affecting the agricultural environment, accumulation of heavy metals, and contamination with small toxic particles.

When these toxic elements enter the human body through agricultural products, people suffer from various health consequences, such as neurological and bone marrow disorders, metabolic disorders, infertility, biological function disruption at the cellular level, and respiratory and immune disorders. The need for agroecological monitoring is reflected in the many deaths due to the toxic effects of pesticide/fertilizer residues. Therefore, monitoring pesticide residues in the environment is an emergency task. Regular monitoring of pesticide residues also provides information on whether levels are within or outside acceptable limits.

Currently, several methods for monitoring agricultural ecosystems are available, including gas chromatography, high-performance liquid chromatography, mass spectrometry, and others. All of these technologies can easily detect and measure pollutants in agricultural samples as well as in the environment. Meanwhile, although the specificity, sensitivity, and reproducibility of these measurements are undeniable, the application of this method is severely limited by time, high cost, and the need for sophisticated equipment and qualified personnel. Thus, there is a need for a simple, fast, and economical method using NANOSENSORS for monitoring these agricultural pollutants.

Pesticides are widely used in agricultural systems to prevent, control or kill pests, insects, weeds, and fungi to enhance the agricultural ecosystem’s productivity. The use of pesticides continues indiscriminately, which leads to contamination of groundwater and accumulation in food sources, severely damaging non-target species such as humans and animals. Human exposure to pesticides can affect health in different ways and lead to many health issues. The search for a fast, sensitive, specific, accurate, and easy-to-use method for detecting pesticide residues has led to the introduction of nanosensors, which are excellent replacements for traditional methods due to their cost-effectiveness, small size, portability, extreme sensitivity, and reduced detection time.

Nanosensors are basic nanoscale devices designed to identify specific molecules, biological components, or environmental conditions. These sensors are very specific, practical, inexpensive, and detect at a much lower level than macro-scale sensors. The 3 components involved in the typical operation of a nanosensor device include;

Sample Preparation

This can be a homogeneous or complex suspension of a gas, liquid, or solid. Sample preparation of agricultural ecosystems is very difficult due to pollution, impurities, and disturbance. Samples contain specific molecules, functional groups of organisms or molecules, that the sensor can target easily. These target molecules/ or organisms, called analytes, can be molecules like dyes/dyes, poisons, pesticides, hormones, antibiotics, vitamins, etc; biomolecules like enzymes, DNA/RNA, allergens, etc; ions; gases or vapors; bacteria, fungus, virus, and environmental conditions like temperature, humidity, light, weather, pH, etc.

Recognition

A particular molecule/element recognizes the analyte in the given sample. These recognition molecules are antibodies, chemical enzymes, etc., and have high selectivity, affinity, and specificity, to measure to an acceptable level of an analyte.

Signal conditioning/Signal transduction/Signal transducer

Several signal conditioning methods classify these simple devices into different types such as electrochemical, electronic, optical, piezoelectric, and gravimetric biosensors. These are used to convert the recognized molecules of a sample into electrical signals or computing signals to process and generate the data.

The nanosensor techniques for detection of pesticide/fertilizer residues are explained below:

1). Many optical strategies (optical sensors) have now been adopted for the detection of residual particles of fertilizers or pesticides using recognition elements such as enzymes, antibodies, aptamers, established polymers, and host-guest recognition. These approaches can reliably identify and detect specific pesticide residues.

Moreover, combining recognition elements or components with nanomaterials results in higher sensitivity and very high specificity for immediate use, which is a key requirement for fast and efficient pesticide detection. Basic optical sensors are divided into 4 types depending on the format of their output signal. They are CL (Colorimetric), FL (Fluorescent), SPR (Surface Plasmon Resonance), and SERS (Surface-Enhanced Raman) optical sensors.

2). Another well-known type of nanosensor is the Immuno-Chromatographic Stripe Nanosensor (ICTS), which has been widely tested in POC (Point-Of-Care) analytical devices. The immuno-chromatographic analysis is reported to be used in agriculture ecosystems for monitoring. For example, the immunochromatographic technique described for GM crops detection by using a visible colorimetric readout strategy that only provides YES/NO responses with insufficient sensitivity.

Similarly, ICTS sensors (with gold nanoparticles) are reported to have low sensitivity detection due to their relatively low color density, which restricts their usage. However, the sensitivity is enhanced with various strategies such as increasing signal intensity detection, optimization of labeling method, increasing the re-agent affinity, and changing the shape. Hence, advanced ICTS nanosensors could prove to be a cost-effective tool for detecting pesticide residues in agricultural ecosystems.

3). Electrochemical nanosensors are powerful tools for pesticide residue detection. These are based on cholinesterase enzymes and are designed to detect pesticide residues, especially carbamate and organophosphorus, due to their high sensitivity, selectivity, and painless manufacturing process. However, Enzyme-Based Biosensors have a number of limitations, such as high cost, reduced enzyme activity, and reduced reproducibility.

In addition, enzymes are naturally unstable and denatured under aggressive environmental conditions, which can limit the service life of biosensors, and limit their practical applications. In addition, selectivity can be affected by the presence of various impurities, such as the presence of various heavy metals in biological origin samples. It can also affect the sensitivity and selectivity of the enzymes while detecting, which might lead to false positive results.

Therefore, a non-enzymatic electrochemical biosensor is required. Nanomaterials are good competitors for the creation of Non-Enzymatic Electrochemical Biosensors. A wide range of nanomaterials, including nanoparticles like CuO, CuO-TiO2 and ZrO2, NiO and nanocomposite materials, nanotubes like peptides and carbon nanotubes, are mostly used for the detection of pesticide residues.

Examples of Nanosensors

Nanosensors might be physical/mechanical and chemical sensors. Examples of nanosensors include,

- Used to monitor pollution to detect the presence of several chemicals in gases.

- In plant biology, it can be used to sense the metabolism of plants.

- In neurophysiology, it is used to observe and understand the neurotransmitters in the brain.

- DNA-based fluorescent nanosensors

- Carbon-nanotube-based fluorescent nanosensors

- Quantum-dot-based fluorescent nanosensors

- Nanosensors for magnetic resonance imaging

- Used in other fields such as agriculture, farming, diagnostics and prognostics, plant synthesis, etc.

Advantages and Disadvantages Of Nanosensors

The advantages of nanosensors include the following.

- Available in small sizes

- Requires less power to operate

- Less weight

- Works as data storage systems

- Great sensitivity, accuracy, scalability, efficiency, precision, and specificity

- Easy to execute.

- Provides a high volume ratio.

- Response time is low.

The disadvantages of nanosensors include the following.

- The top-down fabricated nanosensors have limited resolution and are very costly.

- The bottom-up fabricated nanosensors are less efficient, have large scaling, and are highly expensive than others.

Nanosensor Applications

The following are the nanosensor applications

- Communication systems.

- Transportation.

- Medical field.

- Safety and security systems.

- Aerospace.

- Integrated circuits.

- Facilities and building.

Know more about PIR Sensor.

Please refer to this link to know more about Proximity Sensor MCQs.

Thus, this is all about an overview of a nanosensor. These are developed for future technology in characteristic sizes of nanometer range and work similarly to the sensors. Used for measurement at the single-molecule level, minute particles are efficient at scanning environmental samples, bioimaging, sensing electromagnetic radiation, and many more.