There are a lot of industries that generate various waste particles while carrying out various manufacturing processes. One such type of waste is particulate matter. Such type of waste will have to be removed before the gases are released into the environment. Otherwise, they may pose a serious threat to the environment and also cause various health hazards like lung infection and bronchitis. Fine elements having a size of fewer than 2.5 microns and these are difficult to remove. They cannot be removed by simple filters or chimneys. So, in order to get rid of such fine particulate matter, a highly advanced device called the electrostatic precipitator is used.

What is an Electrostatic Precipitator?

An electrostatic precipitator is a device that is capable of removing undesirable particles from air or any other gases. It takes the help of electric charges in order to remove dust particles. The precipitator is capable of applying energy to the particulate matter without hampering the flow of gases. The electrostatic precipitators were initially used for various industrial processes. Today, it is used to control air pollution by removing particles from different gases. It is also used effectively in fossil-fuel power-generating stations.

Working Principle of Electrostatic Precipitator

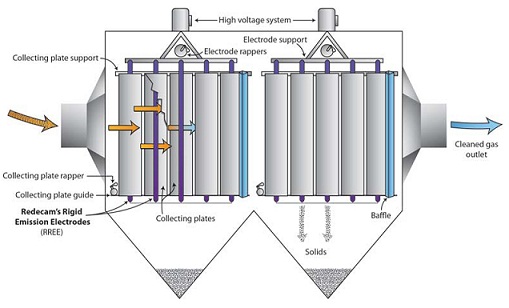

An electrostatic precipitator consists of two electrodes out of which one electrode is positive and the other electrode is negative. The negative electrode is nothing but a wire mesh and the positive electrodes are in the form of plates. The negative electrodes are attached to a negative terminal and positive plates are connected to a positive terminal of the DC source.

The negative electrodes and the positive plates are placed vertically in the electrostatic precipitator one after another. Air is present between the electrodes and because of the high negativity of the negative electrodes, a corona discharge may occur. The air molecules between the electrodes may become ionized resulting in the generation of plenty of free electrons and ions.

The Process Involved in Electrostatic Precipitator

Electrostatic precipitators are extremely important tools from the industrial point of view. They are used in the cleaning of flue gases. They can help reduce particle pollution by removing particles whose sizes are nearly 1 micron (0.00004 inches) in diameter. Some precipitators can also remove particles of 0.01 micron. They are also capable of handling large volumes of gas at different temperatures.

Construction and Working of an Electrostatic Precipitator

An electrostatic precipitator basically consists of a stack of flat vertical metal plates and a row of thin vertical wires. The plates have a separation of fewer than 0.5 inches to about 7 inches (about between them. The distance between the plates depending on the particular application. The stream of gases is made to flow horizontally through the stack of plates and between the rows of vertical wires. A negative charge of thousands of volts is applied between the plates and the wires. This helps to remove the dust particles from the gas stream.

Electrostatic Precipitator Construction

This entire arrangement is placed inside a metallic container. On one side of the container, an inlet for the impure gases is present and on the opposite side, an outlet is provided for the filtered gases. As soon as the impure gases enter the metallic container, the dust particles collide with the free electrons present between the electrodes. The free electrons will then get attached to the dust particles. As a result, the dust particles will become negatively charged.

These negatively charged particles will get attracted by the positive plates. This will cause the charged dust particles to move towards the positive plates. Here, the dust particles will become neutral and they will fall down due to gravitational force. These positive plates are called collecting plates.

Different types of Electrostatic Precipitator

Here, we have mentioned the different types of electrostatic precipitators:

Dry Electrostatic Precipitator

This type of precipitator collect the pollutants in a dry state and hence they are called dry electrostatic precipitators. The dust particles are collected from a stream of air. The particles are ionized and then they become electrically charged. They are then made to flow through the electrodes. The dust particulars which are removed from the stream of air are collected in a hopper and from there, they are extracted out.

Wet Electrostatic Precipitator

Wet electrostatic precipitators are meant to remove wet particles like resin, oil, paint, tar, etc. They are used in various industries where the chances of an explosion are quite high. The particles are given an electric charge as they pass through the corona. The collectors are sprayed with water and the particles are collected from the sludge.

Advantages

The advantages of electrostatic precipitator are

- The electrostatic precipitators have excellent efficiency and they can be used to remove 99% of the dust particles from the impure air.

- They are capable of collecting both dry as well as wet pollutants. The dry precipitators collect the dry pollutants whereas the wet precipitators collect the wet pollutants.

- The electrostatic precipitators have low operating costs and they are quite economically feasible in the long run.

Disadvantages

The disadvantages of electrostatic precipitator are

- The electrostatic precipitators have a very high capital cost which makes it unsuitable for the small-scale industries.

- The device requires a very large space to operate properly.

- The electrostatic precipitators cannot be used to remove gaseous pollutants. They are only suitable for dry and wet pollutants.

Applications of Electrostatic Precipitators

An electrostatic precipitator is used in the industries for various applications. Here, we have mentioned some of the most important applications of electrostatic precipitators:

- It is installed in steam plants to remove the dust from impure gases.

- It can be used in chemical plants to remove oil mists and acid mists.

- It removes the bacteria & fungus in various medical applications.

- Ir is used in air conditioning systems for purifying the air.

So, this is all about an overview of electrostatic precipitators. We can see that an electronic precipitator is an extremely important device from an industrial point of view. The device has a huge range of applications. It is specially used in large industries of purification of gases. It is also quite cost-effective in the long run. What, according to you, is the main disadvantage of an electrostatic precipitator?