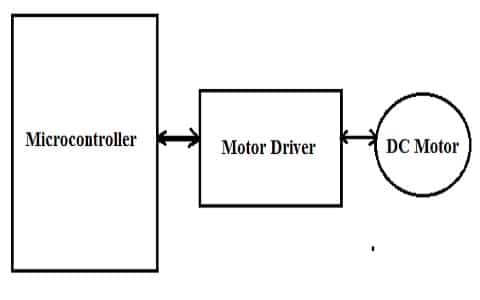

Interfacing a motor driver with a microcontroller is a fundamental step in various electronic projects, especially those involving robotics and automation. The motor driver serves as the bridge between the microcontroller’s digital signals and the power-hungry motors, allowing precise control over their direction and speed. One commonly used motor driver is the L293D, a versatile integrated circuit. However, successful integration requires careful consideration of certain precautions to ensure a seamless and trouble-free operation. In this article, we will explore these precautions to help you navigate the complexities of connecting a motor driver to a microcontroller.

Understanding the Basics: The Motor Driver and Microcontroller:

Before delving into precautions, let’s establish a foundational understanding of the components involved. The motor driver, in this context, acts as an intermediary between the microcontroller and the motor itself. It is designed to handle the higher current and voltage requirements of motors, providing a level of abstraction that shields the delicate microcontroller from potential damage.

Connecting a Motor Driver to a Microcontroller

In this discussion, the L293D motor driver will be used as a reference. The L293D is an H-bridge motor driver integrated circuit, allowing control over the direction and speed of DC motors. The key pins include:

Enable Pins (EN1 and EN2): Used to enable or disable the motor outputs. Pulse Width Modulation (PWM) signals applied to these pins control motor speed.

Input Pins (Input 1, Input 2, Input 3, and Input 4): These pins determine the motor’s direction. Configuring these pins in specific combinations dictates the motor’s rotation.

Output Pins (Out1, Out2, Out3, and Out4): Connected to the motor terminals, these pins drive the motor based on the input signals.

Now, let’s explore the precautions essential for a successful integration.

1. Power Supply Compatibility: Match Voltages and Currents

One of the critical precautions when interfacing a motor driver with a microcontroller is ensuring compatibility between the power supply requirements of both components. The motor driver often operates at higher voltage levels than the microcontroller. Check the datasheets of both the motor driver and the microcontroller to guarantee that their voltage specifications align.

Additionally, motors draw considerable current, especially during startup. Ensure that the power supply can provide sufficient current to meet the demands of both the motor and the motor driver. Inadequate current supply can lead to erratic behavior, diminished performance, or even damage to the components.

2. Decoupling Capacitors: Stabilizing Power Lines

Integrating decoupling capacitors into the circuit is a crucial precautionary measure. These capacitors help stabilize the power lines and minimize voltage fluctuations. Motors, being inductive loads, can introduce noise and voltage spikes back into the power supply lines, potentially affecting the sensitive microcontroller.

Place decoupling capacitors close to the power pins of the motor driver and the microcontroller. This placement helps mitigate the impact of sudden changes in current and ensures a more stable power supply for both components.

3. Grounding: Create a Common Ground Reference

Establishing a common ground reference is paramount for the proper functioning of the integrated system. Connect the ground of the microcontroller, motor driver, and power supply together to avoid ground loops. Ground loops can introduce unwanted noise into the system, leading to erratic behavior and potentially damaging the components.

Incorporate a separate ground wire for the motor, ensuring that the motor current does not flow through the microcontroller’s ground path. This separation helps prevent interference and maintains the integrity of the microcontroller’s ground reference.

4. Current Limiting Resistors for Microcontroller Inputs

Microcontrollers typically operate at lower voltages than motor drivers. When connecting microcontroller output pins to the input pins of the motor driver, use current-limiting resistors to protect the microcontroller from potential damage due to excessive current.

These resistors restrict the current flowing into the input pins of the motor driver, preventing overloading of the microcontroller pins. Consult the datasheets of both the microcontroller and the motor driver to determine the appropriate resistor values for the specific application.

5. Diodes for Back EMF Protection

Motors generate Back Electromotive Force (EMF) when their direction is suddenly changed, or they are abruptly stopped. This back EMF can damage the motor driver and other components if not properly managed. To address this, place diodes (known as flyback or freewheeling diodes) across the motor terminals.

These diodes provide a path for the back EMF to circulate safely, preventing voltage spikes that could otherwise damage the motor driver and other components. Ensure the diodes are rated to handle the maximum current and voltage expected in the system.

6. Heat Dissipation: Adequate Cooling for Motor Driver

Motor drivers can generate heat, especially during prolonged use or when driving high-current motors. To prevent overheating and potential damage to the motor driver, implement proper heat dissipation measures. This may include attaching heat sinks to the motor driver IC or providing sufficient ventilation in the enclosure.

Monitor the temperature of the motor driver during operation and ensure it stays within the specified operating range. Excessive heat can lead to performance degradation and, in extreme cases, permanent damage to the motor driver.

7. Proper Wiring and Signal Integrity: Avoid Signal Cross-talk

Carefully plan and execute the wiring between the microcontroller, motor driver, and motor. Keep signal wires away from high-power lines, and use twisted pair cables for better noise immunity. Proper cable management helps prevent signal cross-talk and interference, ensuring that the control signals from the microcontroller reach the motor driver accurately.

Shielded cables can further protect against external electromagnetic interference. When routing wires, consider the physical layout to minimize the chances of induced noise affecting the control signals.

8. Start with Low Power: Gradual Testing and Debugging

When first connecting the motor driver to the microcontroller, start with low power. Gradually increase the power to observe how the system behaves. This cautious approach allows you to identify and address any issues in a controlled manner, minimizing the risk of damage to components.

Use this initial testing phase to verify the correctness of your wiring, the effectiveness of your power supply, and the appropriateness of your control signals. If issues arise, you can troubleshoot and make adjustments before applying full power to the system.

9. Fuse Protection: Safeguarding Against Overcurrent

Incorporate fuses in the circuit to provide an additional layer of protection against overcurrent conditions. Fuses act as sacrificial components that break the circuit when the current exceeds a specified threshold. This protects the more expensive and sensitive components, such as the microcontroller and motor driver, from damage caused by excessive current.

Choose fuses with ratings that align with the maximum expected current in your system. Be aware that different sections of your circuit may have distinct current requirements, so select appropriate fuses for each segment.

10. Comprehensive Testing: Validate Under Various Conditions

Once the initial testing at low power is successful, gradually increase the complexity of your tests. Validate the system under various conditions, including different motor speeds, direction changes, and load variations. Comprehensive testing helps ensure that your motor driver and microcontroller can handle the full range of scenarios they might encounter in practical applications.

During testing, monitor the temperature of the motor driver, check for any abnormal behavior, and verify that the control signals are accurately translating into motor movements. Address any issues promptly to prevent long-term damage.

Interfacing a motor driver with a microcontroller is a pivotal step in creating dynamic and responsive electronic systems, particularly in the realm of robotics and automation. However, it comes with inherent challenges and risks that necessitate careful consideration of various precautions. From power supply compatibility to signal integrity, each precaution in connecting a motor driver to a microcontroller plays a crucial role in ensuring the reliability and longevity of the integrated system.