Paper capacitors are among one of the basic types of capacitors. Generally, in a capacitor the conducting material is separated by the dielectric. Based on the variant that is utilized as dielectric different types of capacitors are formed. The construction of this capacitor is similar to that of other capacitors, for example, plastic capacitors. The only difference between the other capacitors and this capacitor is that the dielectric chosen is of paper type.

What is a Paper Capacitor?

A capacitor that is constructed with a paper as the dielectric medium which is capable enough of storing the electric charge in it is defined as a paper capacitor. These are the capacitors that prefer fixed amounts of the charge value to be stored. Hence these capacitors categorized under the fixed type ones. To take care or protect the dielectric from the environmental effects it is soaked into wax or oil. These capacitors offer a fixed amount of capacitance.

Construction:

The construction of this type of capacitor is simple. It is based on the sheet of paper chosen. Hence based on the construction, these are classified into two types. They are:

- Paper Sheet

- Metalized Paper

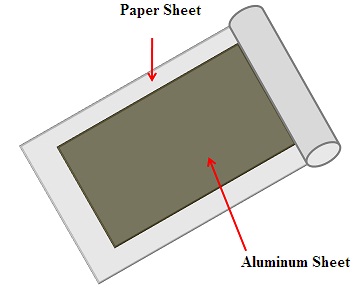

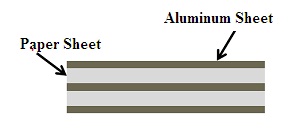

Paper Sheet Type Capacitor

- In this case, the capacitor is constructed by placing a sheet of paper in between the aluminum sheets.

- The sheet of paper that is placed in between the aluminum sheets acts as the dielectric.

- The aluminum sheets act as the electrodes of the capacitor.

- Hence the sheet of paper is not a good conductor. So, the flow of the carriers and the passing of the electric current are not possible.

Paper Capacitor with Paper Sheet

- But the possibility is that the electric field is allowed to pass through it. Therefore the barrier between the electrodes is the sheet of paper.

- These sheets further are rolled in the form of a cylinder and the wire heads are attached. Finally, these are coated using wax or any plastic resin so that these acts as protectants from the environment moisture that is present in the air.

- In this way, this type of capacitor with a sheet of paper is constructed.

Metalized Paper Capacitor

- The paper sheet in this type of capacitor is built with the firm coating of either zinc or aluminum on it.

- After the coating is applied it is rolled just like the cylinder.

- These coated parts act as electrodes and the sheet of paper the same as before considered being dielectric.

- The roll of the cylinder is further provided with a coating of plastic resin or the wax. So that these capacitors are protected from the environmental constraints.

- While using the coating of zinc the drawback is that because of the chemical reactions zinc gets easily destroyed. So aluminum is widely preferred in this type of capacitor.

- Because of the direct coating on the paper in this type, the capacitor size is small compared to the paper sheet capacitor.

Metalized Paper Capacitor

In this way, the capacitor with the metalized layer is constructed.

Working:

This is a capacitor that is constructed in such a way that its capacitance value is fixed. In this type of capacitor, there is the absence of electrolyte so it functions as a general parallel plate capacitor.

Capacitor Values

The value of this capacitor can be identified by following various steps:

- The number present on the capacitor represents the capacitance of the respective capacitor in terms of pico-farads.

- If in the 3-digit number the third represented number is ‘0’. Then the value represents P.

- If the printed number is of three digits then the third digit represents the number of zeroes.

Some of the capacitors follow color coding. Based on this the values of capacitors and their types are found. Paper capacitor ranges in between 300 pico Farads to 4 micro Farads. It’s working voltage exceeds rarely about 600 volts.

Paper Capacitor Advantages and Disadvantages

The advantages of this capacitor are classified under the category of the fixed value of capacitors. These capacitors provide fixed amounts of capacitance. The capacitance amount is fixed during manufacturing by the manufacturer.

The disadvantage or the drawback of using this capacitor is that it gets easily affected due to the moisture content that is present in the air. Because of these absorbing nature insulating nature of the dielectric becomes affected.

Applications

There are various applications of the paper capacitors. Some of them are:

- This can be used in various electrical and electronic applications.

- This can be utilized in filtering applications.

- In the high voltage required applications these are used.

- In the high current requirements, these capacitors are used.

This capacitor designing can be very simple as It is a fixed capacitor. Which paper capacitor you have recently used?